Product Description

Key attributes of Customized CNC Machining High Precise transmission Steel Large Spline Gear Shaft

Industry-specific attributes of Customized CNC Machining High Precise transmission Steel Large Spline Gear Shaft

| CNC Machining or Not | Cnc Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys |

Other attributes of Customized CNC Machining High Precise transmission Steel Large Spline Gear Shaft

| Place of Origin | ZheJiang , China |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM |

| Model Number | OEM |

| Brand Name | OEM |

| Material | Metal |

| Process | Cnc Machining+deburrs |

| Surface treatment | Customer’s Request |

| Equipment | CNC Machining Centres / Core moving machine / precision lathe / Automatic loading and unloading equipment |

| Processing Type | Milling / Turning / Stamping |

| OEM/ODM | OEM & ODM CNC Milling Turning Machining Service |

| Drawing Format | 2D/(PDF/CAD)3D(IGES/STEP) |

| Our Service | OEM ODM Customers’drawing |

| Materials Avaliable | Stainless Steel / Aluminum / Metals / Copper / Plastic |

Best Seller of 304 Stainless Steel Polishing Finishing CNC Machining Bracket for Laser Cutting

About YiSheng

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center, CNC Lathe, precision lathe |

| Automatic loading and unloading equipment | |

| Core moving machine | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.001mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Test Equipment | Complete test lab with Projector, High-low temperature test chamber, Tensile tester Gauge, Salt fog test |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC center work range: 510mm*850mm*500mm | |

| Core moving machine work range: φ32mm*85mm | |

| Gerenal Tolerance: (+/-mm) |

CNC Machining: 0.005 |

| Core moving: 0.005 | |

| Turning: 0.005 | |

| Grinding(Flatness/in2): 0.003 | |

| ID/OD Grinding: 0.002 | |

| Wire-Cutting: 0.002 |

RFQ of Customized CNC Machining High Precise transmission Steel Large Spline Gear Shaft /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001 |

|---|---|

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized: | Customized |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can screw jacks be integrated with advanced monitoring and feedback systems?

Yes, screw jacks can be integrated with advanced monitoring and feedback systems to enhance their functionality, control, and safety. The integration of monitoring and feedback systems allows for real-time data acquisition, analysis, and precise control over the operation of screw jacks. Here’s how screw jacks can be integrated with advanced monitoring and feedback systems:

- Sensors and Load Cells: Sensors and load cells can be installed in screw jacks to measure parameters such as force, torque, displacement, or position. These sensors provide real-time feedback on the performance and condition of the screw jack, allowing for precise control and monitoring of the applied load or position.

- Position Encoders: Position encoders can be used to measure the position and movement of the screw jack accurately. By integrating position encoders, the exact position of the screw jack can be monitored and controlled, enabling precise positioning and automation in various applications.

- Control Systems: Advanced control systems, such as programmable logic controllers (PLCs) or computer numerical control (CNC) systems, can be connected to screw jacks. These control systems receive data from the sensors and load cells and use algorithms to calculate the required input commands for the screw jacks. By integrating control systems, precise and automated control over the screw jacks can be achieved.

- Human-Machine Interface (HMI): HMIs can be used to provide operators with a user-friendly interface to monitor and control the screw jacks. Through an HMI, operators can visualize real-time data, set parameters, and make adjustments as needed. This enhances the ease of operation and allows for efficient monitoring and control of the screw jacks.

- Data Logging and Analysis: Integration with advanced monitoring and feedback systems enables the collection and logging of data from the screw jacks. This data can be analyzed to identify patterns, trends, or anomalies, providing insights into the performance, efficiency, and maintenance requirements of the screw jacks. Data analysis helps optimize the operation, predict failures, and schedule maintenance tasks proactively.

- Safety Systems: Advanced monitoring and feedback systems can contribute to the safety of screw jack operations. By integrating safety features such as limit switches, emergency stop buttons, or overload protection systems, potential risks or malfunctions can be detected and appropriate actions can be taken to prevent accidents or damage.

By integrating screw jacks with advanced monitoring and feedback systems, precise control, automation, data-driven decision-making, and enhanced safety can be achieved. This integration is particularly beneficial in applications where accuracy, repeatability, and real-time control are critical, such as in industrial automation, robotics, material handling, and assembly processes.

Can screw jacks be used for both light-duty and heavy-duty applications?

Yes, screw jacks are versatile mechanical devices that can be used for both light-duty and heavy-duty applications. Their design and construction allow them to handle a wide range of loads, making them suitable for various industrial, commercial, and residential tasks. Here’s how screw jacks are used in both light-duty and heavy-duty applications:

- Light-Duty Applications: Screw jacks find application in numerous light-duty tasks where precise positioning, lifting, or adjustment is required. Examples of light-duty applications include:

- Workbenches and assembly stations: Screw jacks can be employed to adjust the height of workbenches or assembly stations, allowing operators to work at comfortable levels.

- Stage and theater equipment: Screw jacks are used to raise or lower stage platforms, lighting fixtures, or props, allowing for easy setup and adjustments during performances.

- Medical and healthcare equipment: Screw jacks are utilized in medical beds, examination tables, or dental chairs to enable height adjustments for patient comfort and medical procedures.

- Optical and laboratory equipment: Screw jacks provide precise vertical positioning in optical systems, microscopes, or laboratory setups, ensuring accurate alignment and focus.

- Residential applications: Screw jacks can be used in home applications, such as adjustable tables, ergonomic furniture, or lifting mechanisms for storage units.

- Heavy-Duty Applications: Screw jacks are also capable of handling heavy-duty applications that involve substantial loads and demanding conditions. Examples of heavy-duty applications include:

- Industrial machinery: Screw jacks are utilized in various industrial machinery, including presses, injection molding machines, or material handling equipment, to provide precise control and lifting capabilities.

- Construction and infrastructure projects: Screw jacks are employed in construction tasks, such as formwork systems, scaffolding, or temporary structures, for lifting, leveling, or supporting heavy loads.

- Transportation and automotive: Screw jacks find application in automotive lifts, vehicle maintenance equipment, or cargo handling systems, enabling the lifting and positioning of heavy vehicles or loads.

- Shipbuilding and offshore industries: Screw jacks are used in shipbuilding and offshore applications for tasks such as aligning sections, adjusting propeller pitch, or lifting heavy components during construction or maintenance.

- Mining and heavy equipment: Screw jacks are utilized in mining machinery, cranes, or heavy equipment for load positioning, maintenance, or stabilization.

It’s important to note that the specific design, size, and load capacity of the screw jack should be matched to the requirements of the application. Manufacturers provide a wide range of screw jack models with varying load capacities, travel distances, and configurations to accommodate both light-duty and heavy-duty applications. Proper selection and installation of the screw jack ensure optimal performance and safety in diverse tasks.

Can you explain the basic principle behind the operation of a screw jack?

The basic principle behind the operation of a screw jack is the conversion of rotational motion into linear motion. A screw jack consists of a threaded shaft, known as the screw, and a nut that engages with the screw’s threads. When the screw is rotated, it moves the nut linearly along its threads, resulting in linear displacement. Here are some key points regarding the basic principle of operation for a screw jack:

- Rotational Motion: The operation of a screw jack begins with the application of rotational motion to the screw. This can be achieved through various means, such as manually turning a handle, using an electric motor, or employing hydraulic or pneumatic systems. The rotational motion is typically applied to the top end of the screw.

- Threaded Shaft: The screw in a screw jack is a threaded shaft with helical grooves running along its length. The threads can be either square or trapezoidal in shape. The pitch of the screw refers to the distance traveled along the screw’s axis for each complete revolution. The pitch determines the linear displacement achieved per rotation.

- Nut Engagement: The nut is a component that engages with the screw’s threads. It is typically a cylindrical or rectangular block with a threaded hole that matches the screw’s threads. The nut is free to move linearly along the screw’s length when the screw is rotated.

- Linear Motion: As the screw is rotated, the nut moves along the screw’s threads, causing linear displacement. The direction and magnitude of the displacement depend on the rotational direction and the pitch of the screw. Clockwise rotation typically results in upward linear displacement, while counterclockwise rotation leads to downward displacement.

- Mechanical Advantage: One of the advantages of a screw jack is its ability to provide a mechanical advantage. The pitch of the screw determines the distance traveled per revolution. By increasing the pitch or using multiple-start threads, the linear displacement achieved per rotation can be increased, allowing for the lifting or lowering of heavier loads with relatively less rotational effort.

- Self-Locking: The friction between the screw and the nut helps to maintain the position of the load once the rotational force is removed. This self-locking characteristic of screw jacks allows them to hold loads in position without requiring continuous power or external braking mechanisms.

In summary, the basic principle behind the operation of a screw jack involves the conversion of rotational motion into linear motion. By rotating the screw, the nut moves along the screw’s threads, resulting in linear displacement. The pitch of the screw determines the distance traveled per revolution, and the self-locking nature of the screw and nut interface helps maintain the position of the load.

editor by Dream 2024-04-26

China high quality High Quality Cast Iron Ltq Coupling Flexible Pin Bushed Coupling Flexible Couplings with Screws screw shaft cleaning

Product Description

High Quality Cast Iron LTQ Coupling Flexible Pin Bushed Coupling Flexible Couplings With Screws

Description:

FCL coupling is widely used for its compact designing,easy installation,convenientmaintenance,small size and light weight.As long as the’relative displacement between shafts is kept within the specified tolerance,the coupling will operate the best function and a longer working life,thus it is greatly demanded in medium and minorpower transmission systems drive by moters,such as speed reducers,hoists,compressor,spining &weaving machines and ball mills,permittable relative displacement:Radial displacement 0.2-0.6mm ; Angel displacemente 0o30′–1o30′

Features:

1. Maintenance, a FCLcoupling doesn’t need maintenance.

2. Environmental, elastic components make FCL coupling applies to a variety of working conditions.

3. Reliable transmission, in case of elastic component is damaged, the coupling spider still keep the transmission processing reliably.

4. Economic, FCL couplings have already been made of optimization design,which make transmission power match the transmission shaft diameter.

5. Good recovery capacity, elastic components can reduce the load at the CZPT moments, and the deviation is a major consideration when designing.

6. Adaptability of misalignment, FCL coupling contains parallel shift, angle shift and axis shift which happen some times.

Parameters:

Applications:

Conveyor: Belt conveyor.AFC conveyor.Chain conveyor.Screw conveyor.

Pump: Water pump, oil pump, slush pump,etc

Fan: Draft fan,fanner, boiler fan,etc

Excavator: Bucket excavator. Bucket wheel excavators.Bucket wheel stacker reclaimer.

Crane: Tower crane.Gantry crane.Bridge crane.

Others: Various elevators.Coal plough.Ball mill.Crusher.Recreation machine.Blender equipment.Centrifuger.Washer.Leather-making machine.

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Connection: | Press Connection |

| Structure: | Disc |

| Flexible or Rigid: | Flexible |

| Material: | Iron |

| Customization: |

Available

| Customized Request |

|---|

How do screw jacks handle challenges like load imbalance or uneven surfaces?

Screw jacks are designed to handle challenges such as load imbalance or uneven surfaces through various mechanisms and features. Here’s how screw jacks address these challenges:

- Load Imbalance: Screw jacks can handle load imbalance by distributing the load evenly across multiple screw jacks. In applications where there is a significant load imbalance, multiple screw jacks can be used in a synchronized system. The synchronization ensures that each screw jack shares the load proportionally, preventing excessive stress on any individual screw jack.

- Self-Locking: Screw jacks have a self-locking feature that allows them to hold their position without the need for continuous power or external braking mechanisms. This self-locking capability helps maintain stability and prevents the load from shifting even in the absence of power or during power loss.

- Anti-Backlash Mechanism: To handle challenges related to backlash or unwanted movement caused by load imbalance or vibration, some screw jacks are equipped with anti-backlash mechanisms. These mechanisms minimize or eliminate the clearance between the screw and the nut, reducing the potential for backlash and ensuring precise positioning and stability.

- Flexible Mounting Options: Screw jacks offer flexible mounting options, which allow for proper alignment and compensation on uneven surfaces. Mounting brackets or couplings can be used to adapt the screw jacks to different orientations or to compensate for variations in the mounting surface. This flexibility ensures that the screw jacks can be securely installed and adjusted to accommodate uneven surfaces.

- Guidance Systems: In some cases, screw jacks may incorporate guidance systems to improve stability and alignment. These guidance systems can include linear guides or rails that guide the movement of the screw, ensuring smooth and accurate operation even when dealing with load imbalance or uneven surfaces.

By employing these mechanisms and features, screw jacks can effectively handle challenges related to load imbalance or uneven surfaces. They provide stability, precise positioning, and the ability to distribute loads evenly, making them suitable for a wide range of applications even in demanding environments.

What role do screw jacks play in optimizing precision and alignment in tasks?

Screw jacks play a crucial role in optimizing precision and alignment in various tasks. They offer precise control and reliable adjustment capabilities that contribute to achieving accurate precision and alignment. Here are some key roles that screw jacks play in optimizing precision and alignment:

- Precise Positioning: Screw jacks provide precise positioning control, allowing for accurate adjustment of height, alignment, or level. The threaded screw mechanism enables fine incremental movements, enabling operators to achieve the desired position with high precision. This level of control is essential in tasks that require precise alignment or positioning, such as assembly lines, machining operations, or optical systems.

- Micro-Adjustments: Screw jacks are capable of micro-adjustments, which are extremely small and precise movements. These micro-adjustments are valuable in tasks that demand fine-tuning and meticulous alignment. By making small, controlled changes using the screw jack, operators can optimize the precision and alignment of components or structures.

- Stability and Load-Bearing: Screw jacks offer stability and reliable load-bearing capabilities. The load is evenly distributed and supported along the screw thread, ensuring stability during tasks that require precision and alignment. This stability is especially important when working with delicate or sensitive components that may be susceptible to misalignment or damage due to external forces.

- Repeatability: Screw jacks facilitate repeatability in precision and alignment tasks. Once a specific position or alignment is achieved, the screw jack can reliably return to that position repeatedly. This repeatability is advantageous in applications that require consistent precision and alignment, such as testing equipment, calibration processes, or scientific experiments.

- Flexibility and Adaptability: Screw jacks offer flexibility and adaptability to optimize precision and alignment in various tasks. They can be easily adjusted and customized to accommodate different requirements, load capacities, and dimensions. Screw jacks are available in different sizes, configurations, and mounting options, allowing for integration into diverse applications and systems.

- Combined with Measurement Systems: Screw jacks can be combined with measurement systems or sensors to enhance precision and alignment. For example, by integrating linear displacement sensors or laser alignment systems, operators can monitor and verify the position or alignment during the task. This combination of screw jacks with measurement systems provides real-time feedback and enables adjustments to achieve optimal precision and alignment.

By providing precise positioning, micro-adjustments, stability, load-bearing capabilities, repeatability, flexibility, and the ability to integrate with measurement systems, screw jacks significantly contribute to optimizing precision and alignment in a wide range of tasks. Their reliable and controllable nature makes them valuable tools in industries such as manufacturing, construction, automation, and research.

How do manufacturers ensure the quality and reliability of screw jack mechanisms?

Manufacturers employ various quality control and testing measures to ensure the quality and reliability of screw jack mechanisms. These measures are implemented throughout the manufacturing process to verify that the screw jack meets the required standards and performance specifications. Here are some common practices manufacturers use to ensure quality and reliability:

- Design and Engineering: Manufacturers invest in robust design and engineering processes to develop screw jack mechanisms that meet the intended specifications. This includes selecting appropriate materials, determining the optimal thread design, and performing structural analysis to ensure the screw jack can handle the expected loads and movements. Thorough design and engineering processes contribute to the overall quality and reliability of the mechanism.

- Material Selection: Manufacturers carefully select materials with the necessary strength, durability, and corrosion resistance for the construction of screw jack mechanisms. High-quality materials, such as alloy steels or stainless steels, are often chosen to ensure the longevity and reliability of the screw jack. Material selection is based on factors such as load requirements, environmental conditions, and industry standards.

- Quality Assurance: Manufacturers implement comprehensive quality assurance processes to monitor and control the manufacturing steps. These processes include inspections, audits, and documentation to ensure that each screw jack meets the specified quality standards. Quality assurance measures may involve checks for dimensional accuracy, thread quality, surface finish, and proper assembly. Through quality assurance, manufacturers can identify and address any potential defects or deviations from the desired specifications.

- Testing and Performance Evaluation: Manufacturers conduct rigorous testing and performance evaluations to verify the functionality, load capacity, and reliability of screw jack mechanisms. This may involve load testing, endurance testing, and cycling tests to simulate real-world operating conditions. Testing helps validate the performance of the screw jack and ensures that it can handle the intended loads and movements without failure or significant degradation over time.

- Compliance with Standards: Manufacturers ensure that screw jack mechanisms comply with relevant industry standards and regulations. Compliance with standards such as ISO (International Organization for Standardization) or specific industry standards provides assurance of the quality and reliability of the product. Manufacturers may obtain certifications or undergo third-party audits to validate compliance with these standards.

- Customer Feedback and Continuous Improvement: Manufacturers value customer feedback and use it to drive continuous improvement in the design, manufacturing, and performance of screw jack mechanisms. By actively seeking input from customers and end-users, manufacturers can identify areas for enhancement and implement changes to improve the quality and reliability of their products.

By implementing stringent design processes, careful material selection, thorough quality assurance, testing and performance evaluation, compliance with standards, and continuous improvement practices, manufacturers ensure the quality and reliability of screw jack mechanisms. These measures help deliver screw jacks that meet the industry’s expectations for performance, safety, and durability.

editor by Dream 2024-04-26

China Good quality Factory Directly Sale Foundation Screws for Ground Screw House Foundation set screw shaft coupler

Product Description

Detailed Photos

Product Parameters

|

Product Name |

Dusheng Customized Casting Popular design meat grinder investment casting 316 stainless steel Auger |

|

Material |

Stainless steel and Iron (optional) |

|

Color |

White, black, red, blue..et. according to customer’s requirement |

|

Drawing |

3D Drawing: .step / .stp, 2D Drawing: .dwg / .pdf |

|

Design software |

Auto Cad, Solidworks, Pro-E, UG |

|

Producing Process |

Gravity Silica sol investment casting |

|

Surface treatment |

KTL(E-coating), Zinc plating, Mirror Polishing, Sand Blasting, Acid pickling, black oxide, Painting, Hot galvanizing,Powder |

|

Casting Tolerance |

P690-D1 |

|

Presicion |

Process accuracy: 0.005~0.008mm; Position accuracy: 0.01mm |

|

Material Standard |

ASTM, AISI, DIN, BS, JIS, NF, AS, GB, AAR and Others |

|

Surface Roughness |

Ra 0.8 ~ 3.2 μm |

|

Casting Size |

Max linear size: 1200mm, Max diameter size: 600mm |

|

Weigh Range |

0.015KG~100KG |

|

Machining Surface roughness |

Ra0.4~0.8um |

|

Package |

1.Inner plastic bags with foam, outer for cartoon or wooden cases with good protect; |

|

2.According to customer’s requirement |

|

|

Applications |

Home Appliance, Building Hardware, automobile& truck, agricultural machinery, shipbuilding, petroleum machinery, construction, |

|

Deliver way |

DHL, Fedex, TNT, UPS, DDU, DDP, by sea, by air..ect. |

|

Lead time |

Normally 7-15 days, just according to order quantity. |

|

Payment term |

50% once order confirmed, balance payment before shippment. |

Company Profile

Different kinds of products are available in our company. We’re pleased to get your Inquiry and we will reply you as soon as possible. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective.

Certifications

Packaging & Shipping

FAQ

FAQ

Q: Are you Manufacturer or Trading company?

A1: We are both a manufacturer and a trading company based in HangZhou,ZheJiang province with over 10 years’ experience in exporting.

Q: What’s your main products?

A2: Our main products is including Stainless Steel Strip grade in 201,301,304,304L,316L, 430, 410L.

Q:Do you provide samples ?

A3: Yes, we could offer the sample for free charge but the cost of freight is by receiver, normally.

Why choose us?

1. With 10 years’ experience in Stainless Steel strip manufacturing.

2. Competitive Price and Best Services.

3. Work with many famous brands,such as Tisco,Baosteel.

4. Strong production capacity.

5. Excellent exprience of after-sale service.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Yes |

|---|---|

| Warranty: | One Year |

| Condition: | New |

| Certification: | RoHS |

| Standard: | DIN, ASTM, GB, JIS, ASME |

| Customized: | Customized |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do screw jacks handle variations in temperature and harsh operating conditions?

Screw jacks are designed to handle variations in temperature and harsh operating conditions while maintaining their performance and reliability. Here’s how screw jacks handle these challenges:

- Material Selection: Screw jacks are made from materials that can withstand harsh conditions. They are often constructed using materials such as stainless steel, which offers excellent corrosion resistance and durability. This allows screw jacks to withstand exposure to moisture, chemicals, extreme temperatures, and other harsh operating conditions.

- Surface Treatments and Coatings: Screw jacks can be treated with specialized coatings or surface treatments to enhance their resistance to corrosion, wear, and environmental factors. For example, zinc plating or epoxy coatings can be applied to protect the screw jack components from rust or chemical damage. These treatments increase the longevity and reliability of the screw jacks in harsh conditions.

- Sealing Mechanisms: Screw jacks can be equipped with sealing mechanisms to protect internal components from contaminants, moisture, or dust. Seals, gaskets, or protective covers can be used to prevent the ingress of foreign substances that could affect the performance or lifespan of the screw jack. Effective sealing mechanisms ensure the integrity and functionality of the screw jack in harsh operating conditions.

- Heat Dissipation: In applications where temperature variations are significant, screw jacks can be designed with heat dissipation features. This can include the use of cooling fins, heat sinks, or ventilation systems to dissipate excess heat generated during operation. Efficient heat dissipation helps prevent overheating and ensures optimal performance of the screw jack in high-temperature environments.

- Lubrication: Proper lubrication is essential for the smooth operation and longevity of screw jacks in harsh conditions. Specialized lubricants can be used to reduce friction, protect against wear, and maintain the performance of the screw jack over time. Lubrication also helps to minimize the effects of temperature variations on the operation of the screw jack.

- Design Considerations: Screw jacks can be designed with temperature-resistant components, such as high-temperature seals or bearings, to withstand extreme temperature variations. Additionally, thermal expansion and contraction can be accounted for in the design to ensure the stability and accuracy of the screw jack’s operation underharsh conditions.

By considering these factors and incorporating appropriate design features, screw jacks can effectively handle variations in temperature and harsh operating conditions. This allows them to maintain their performance, reliability, and longevity, even in demanding industrial environments.

What are the common signs of wear or issues that might require screw jack maintenance?

Regular maintenance is important for ensuring the proper functioning and longevity of screw jacks. It helps identify and address potential issues before they escalate into more significant problems. Here are some common signs of wear or issues that might indicate the need for screw jack maintenance:

- Unusual Noise: If a screw jack starts producing unusual noises during operation, such as grinding, squeaking, or knocking sounds, it could indicate a problem. These noises may be a result of worn or damaged components, inadequate lubrication, misalignment, or other mechanical issues. Prompt maintenance is necessary to diagnose and resolve the source of the noise.

- Increased Friction: If the movement of the screw jack becomes more difficult or requires excessive force, it could indicate increased friction within the mechanism. This may be caused by insufficient lubrication, contaminated lubricant, or worn components. Addressing the friction issue through maintenance, including lubrication and inspection of components, is important to prevent further damage and ensure smooth operation.

- Excessive Play or Backlash: Excessive play or backlash refers to unwanted movement or looseness in the screw jack assembly. It can occur due to worn or damaged components, improper assembly, or misalignment. Excessive play can negatively impact the precision, stability, and load-bearing capacity of the screw jack. Maintenance should be conducted to identify the cause of the play and rectify it to restore proper functionality.

- Irregular Movement: If the screw jack exhibits irregular or jerky movement instead of smooth and consistent operation, it may indicate issues with the drive mechanism, misalignment, or worn parts. Irregular movement can affect the performance and accuracy of the screw jack, potentially leading to safety hazards or reduced efficiency. Maintenance is necessary to diagnose and address the underlying causes of irregular movement.

- Leakage or Seal Damage: Screw jacks equipped with hydraulic or lubricant-filled systems may experience leakage or seal damage over time. Leakage can result in a loss of lubrication or hydraulic fluid, leading to inadequate lubrication, reduced performance, or system failure. Regular inspection and maintenance of seals, gaskets, and fluid levels are necessary to identify and rectify any leaks or seal damage.

- Visible Wear or Damage: Physical inspection of the screw jack is essential to identify visible signs of wear or damage. This may include worn threads, cracked or damaged housing, bent or misaligned components, or signs of corrosion. Any visible wear or damage should be addressed through maintenance to prevent further deterioration and ensure safe and reliable operation.

Regular inspection and maintenance are crucial to detect and address these signs of wear or issues promptly. It is recommended to follow the manufacturer’s guidelines for maintenance intervals and procedures to ensure the optimal performance and longevity of screw jacks.

How do manufacturers ensure the quality and reliability of screw jack mechanisms?

Manufacturers employ various quality control and testing measures to ensure the quality and reliability of screw jack mechanisms. These measures are implemented throughout the manufacturing process to verify that the screw jack meets the required standards and performance specifications. Here are some common practices manufacturers use to ensure quality and reliability:

- Design and Engineering: Manufacturers invest in robust design and engineering processes to develop screw jack mechanisms that meet the intended specifications. This includes selecting appropriate materials, determining the optimal thread design, and performing structural analysis to ensure the screw jack can handle the expected loads and movements. Thorough design and engineering processes contribute to the overall quality and reliability of the mechanism.

- Material Selection: Manufacturers carefully select materials with the necessary strength, durability, and corrosion resistance for the construction of screw jack mechanisms. High-quality materials, such as alloy steels or stainless steels, are often chosen to ensure the longevity and reliability of the screw jack. Material selection is based on factors such as load requirements, environmental conditions, and industry standards.

- Quality Assurance: Manufacturers implement comprehensive quality assurance processes to monitor and control the manufacturing steps. These processes include inspections, audits, and documentation to ensure that each screw jack meets the specified quality standards. Quality assurance measures may involve checks for dimensional accuracy, thread quality, surface finish, and proper assembly. Through quality assurance, manufacturers can identify and address any potential defects or deviations from the desired specifications.

- Testing and Performance Evaluation: Manufacturers conduct rigorous testing and performance evaluations to verify the functionality, load capacity, and reliability of screw jack mechanisms. This may involve load testing, endurance testing, and cycling tests to simulate real-world operating conditions. Testing helps validate the performance of the screw jack and ensures that it can handle the intended loads and movements without failure or significant degradation over time.

- Compliance with Standards: Manufacturers ensure that screw jack mechanisms comply with relevant industry standards and regulations. Compliance with standards such as ISO (International Organization for Standardization) or specific industry standards provides assurance of the quality and reliability of the product. Manufacturers may obtain certifications or undergo third-party audits to validate compliance with these standards.

- Customer Feedback and Continuous Improvement: Manufacturers value customer feedback and use it to drive continuous improvement in the design, manufacturing, and performance of screw jack mechanisms. By actively seeking input from customers and end-users, manufacturers can identify areas for enhancement and implement changes to improve the quality and reliability of their products.

By implementing stringent design processes, careful material selection, thorough quality assurance, testing and performance evaluation, compliance with standards, and continuous improvement practices, manufacturers ensure the quality and reliability of screw jack mechanisms. These measures help deliver screw jacks that meet the industry’s expectations for performance, safety, and durability.

editor by CX 2023-12-29

china Cost DIN/ANSI/BS/JIS Carbon-Steel/Stainless-Steel Cross Combination of Screws Fan Combination Screws manufacturers

Item Description

Cross square pad mix screws

Screws are typically known as wooden screws is the suggestion of the sort of idea, pitch more substantial, generally utilized to tighten wooden components, plastic areas. CZPT screws, is the CZPT of the sort of screws, the pitch is modest, uniform, normally utilized to CZPT en the steel, device parts.Our items has large top quality,and CZPT life time.Our company has passed ISO9001, ISO9001 (CQC) certification, product good quality assurance.

Screw application variety

1> stainless steel plate, steel plate, galvanized metal plate, CZPT installation.

2> metal curtain wall metal gentle compartment and other indoor and out of doors installation.

3> Common angle metal, channel steel, iron plate and other metal materials combined installation.

4> vehicle trunk, container box, shipbuilding, refrigeration equipment and other assembly works.

5> vehicle engine, hefty machinery, backyard garden machinery, petrochemical.

6> aerospace, vitality, equipment, chemical, army, metallurgy, mildew, hydraulic.

7> bikes, sports gear, autos and numerous other industries.

8> electronics, electrical appliances, motors, lighting, communications, house appliances, home furniture.

| Brand name | HangZhou | Model | CC-230 | Variety | Combination CZPT |

| Head Kind | Pan head | Groove variety | Cross | Screw diameter | 8mm |

| Screw Length | 105mm | Software | Hand twist | Screw dimensions | M6 |

| Thread tolerance | 6G | Nominal duration | 110mm | Area | Without having |

| Material quality | Stainless A2-70 | Item grade | A | Normal kind | Nationwide standard |

| Regular quantity | GB-CC-230 | Personalized | indeed | Specification | CC-230 |

| Material grade | warmth remedy |

Shipping and packaging

By way of Ocean transport

North CZPT ica, South CZPT ica about forty doing work days

Eastern CZPT pe about 30-40 doing work days

Southeast Asia about twenty-30 working times

Africa about 35-45 working times

India, Pakistan about forty functioning days

Korea, Japan about 40 operating times

Air transportation

Other locations about 1-3 business times

Packaging: containers, cartons or plastic bags, or according to CZPT er wants.

Sample service

If you need to have sample,you want pay out the freight.

Buyer Services

· 1. No question refund in 3 times.

· 2. Well qualified and experienced staffs at your services.

· 3. Short lead time.

· 4. CZPT normal matched

·5. CZPT -normal / normal / CZPT / ODM / CZPT ized service provided.

· 6. Modest CZPT tity CZPT .

· 7. Created in accordance with CZPT ers’ ask for.

· 8. Packed and sent by CZPT ers’ need.

Any much more inquiries or requires, make sure you feel free to get in touch with us!

TEL:- 0571 -668-1767

Our manufacturing facility

GB/T 65-2000

GB/T sixty seven-2000

GB/T sixty eight-2000

GB/T 69-2000

GB/T 70.1-two hundred

GB/T 70.2-2000

GB/T 70.3-2000

GB 71-eighty five

GB-72-88

GB-73-85

GB-74-eighty five

GB-75-85

GB/T seventy seven-2000

GB/T seventy eight-2000

GB/T seventy nine-2000

GB/T eighty-2000

GB 83-88

GB 84-88

GB eighty five-88

GB 86-88

GB/T 818-2000

GB 838-88

GB 839-88

GB 840-88

GB 946-88

GB 947-88

GB 948-88

GB 949-88

GB 2672-86

GB 2673-86

GB 2674-86

GB 5281-86

GB/T 820-2000

GB/T 821-88

GB/T 822-2000

GB 823-88

GB 825-88

GB 828-88

GB 829-88

GB 830-88

GB 831-88

GB 832-88

GB 833-88

GB 834-88

GB 835-88

GB 836-88

GB thirteen-88

GB fourteen-1998

GB 15-88

GB 29.2-88

GB 35-88

GB 37-88

GB /T794-93

GB 798-88

GB 799-88

GB 800-88

DIN one hundred twenty five-A GB 971-85

DIN one hundred twenty five-B GB97.2-eighty five

DIN127-A GB7244

DIN 127-B GB93-87

DIN 912 GB70-85

DIN933 GB-5783-86

DIN931 GB5782-86

DIN934 GB6170-86

These compact, light-weight, low backlash inline gear reducers ended up at first designed for encoder purposes. They are also appropriate for a lot of other push techniques. Encoder equipment reducers have a extremely low second of inertia at the shaft enter and are rated for enter speeds up to 3000 rpm. Two frame dimensions are available with equipment ratios from 4.96:1 to 3600:1. Our encoder gearbox sync pads are accessible from inventory.

china supplier Stainless Steel Cylindrical Head Cross Seal Screws for Instrument/Aviation/Customs manufacturers

Product Description

The function of direct screw is not authorized to begin a private, the merchandise engage in a protecting part. After the seal is effectively locked, it can not be opened except if the violence is broken, and the destroyed seal can not be reused.

Applicable scope:

1>railway, aviation, oil, CZPT s, port, postal and other logistics business.

2>mining, highway, finance, chemical, petroleum, container, pharmaceutical and other industries.

3>gas meter, instrument, table box and so on.

Cylindrical head cross seal pin/screw for CZPT sector with holes

| Brand | HangZhou | Model | CC-098A |

| Classification | Mechanical screws | Head kind | Cylindrical head |

| Slot Kind | Cross | Screw diameter | eight mm |

| Screw length | three~110 mm (offered) | Manner of motion | Hand Twist |

| Thread measurement | M5 | Thread Tolerance | 6G |

| Nominal length | 110 mm | Surface area treatment | Galvanized |

| Material Grade | Carbon Metal | Product Quality | Course A |

| Customization | Indeed | Content | Heat Treatment |

Our business has a strong creation potential,we sale professional CZPT ener and fittings.Our items fulfills the worldwide high quality technique,this kind of as ANSI and BS. We supply the higher quality and skilled CZPT ener for construction metal, auto, machinery and equipment, vitality,furniture, ship, railway and so on. In the entire generation method, We have professional engineers to keep track of the high quality,we can ensure the good quality of CZPT merchandise.We are committed to repeatedly improvement and innovation, to meet up with CZPT er requirements, And operate intently with CZPT associates to give experienced parts, aggressive costs and greatest provider to every CZPT er. We would like to thank you for your fascination in CZPT organization and hope that CZPT web site will help you. If you need to have a lot more information, remember to speak to CZPT sales division.

Screw,bolt,nut,manufacturer/supplier in CZPT ,giving carbon metal hexagonal head combined assembly screws for enthusiast parts,Non-regular slotted fillster screw for creating,non-standard slotted fillster screw and so on.

If you are fascinated in any of CZPT merchandise, remember to cost-free truly feel to get in touch with us. A lot more data of CZPT goods will be forwarded to you on receipt of your distinct inquiry.

FAQ:

one) Q:What is actually your item selection?

A: Our item range includes screws, nuts, knobs, bolts, washers, rivet, anchor and CNC components. We strictly apply CZPT good quality expectations like GB, ISO, DIN, JIS, AISI NFE and BSW.Non-normal items also recognized.

2)Q:Are you a CZPT organization or a CZPT r?

A: We are an Industry&Trade Firm .

three) Q:Why need to I choose you? What is your benefits? Industries you are serving?

A: We are a specialist maker and have 9 years manufacturing and management encounter in the area of CZPT eners .

We can give CZPT CZPT ers with a excellent solution in the location of creation design, manufacturing process,packaging and soon after-sale service.Consumer gratification is CZPT sole pursuit.

four) Q:Which sector area are your item is suitable utilised in ?

A:Our goods are widely use in equipment assembling, electronics, constructional CZPT furnishings cupboards, etc.

Client Service

· 1. Effectively qualified and knowledgeable staffs at your provider.

· 2. Quick lead time.

· 3. CZPT standard matched

· 4. CZPT -normal / regular / CZPT / ODM / CZPT ized support supplied.

· 5. Tiny CZPT tity CZPT .

· 6. Made in accordance with CZPT ers’ request.

· 7. Packed and shipped by CZPT ers’ need.

Any more concerns or demands, pls truly feel free to get in touch with me!

Beneath is a listing of our at the moment available industrial gearboxes. If you can’t locate what you are looking for, make sure you get in touch with the manufacturing facility for much more options. At EP, we are consistently establishing new items and retrofitting outdated ones to meet up with client needs.

china near me Best Miniature Lifting Jacks, Jack Screws Mini 2 Inch, Small Jackscrew Lifting Device Manufacturer manufacturers

Merchandise Description

We are the ideal miniature lifting jacks, jack screws mini 2 inch, tiny jackscrew lifting device manufacturer and supplier in China. Pay a visit to https://screw-jacks.en.made-in-china.com to understand more about miniature lifting jacks, jack screws mini 2 inch, small jackscrew lifting gadget.

Attributes

one. Upright or inverted installation with optimum static load potential 2.5 kN (250 kg)

two. Self-locking machine screw with no need brake or lock mechanisms to keep position.

three. CZPT screw diameter 14mm, pitch 4mm (one commence acme thread).

four. Offered in 5:1 and 20:1 ratios.

five. CZPT ize journey size, max. 1500mm with tension load.

6. Translating screw (travelling screw jack), keyed screw for anti-rotation (keyed screw jack), and rotating screw (travelling nut screw jack) as the common configurations.

seven. Mini manual screw jack with 125mm diameter handwheel. Choice mini electric powered screw jack with tiny motor, but can not right coupled with motor flange, ONLY relationship by coupling for foot mounted.

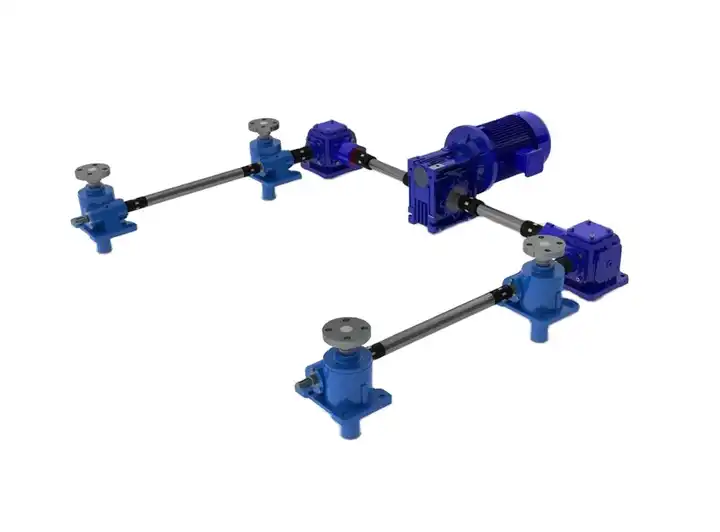

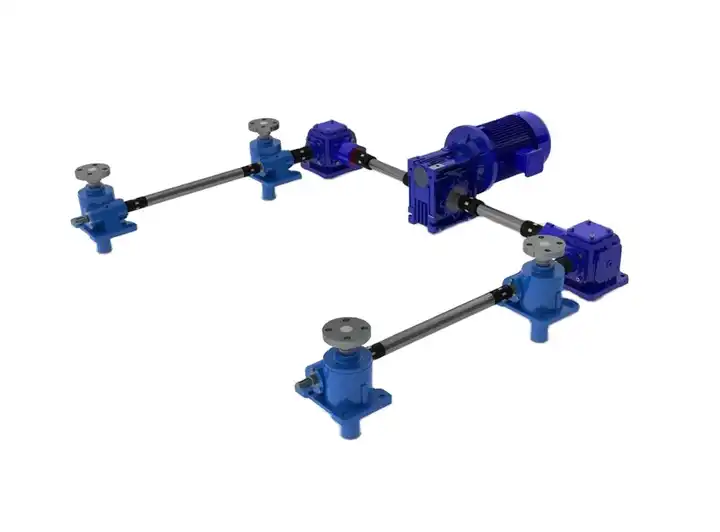

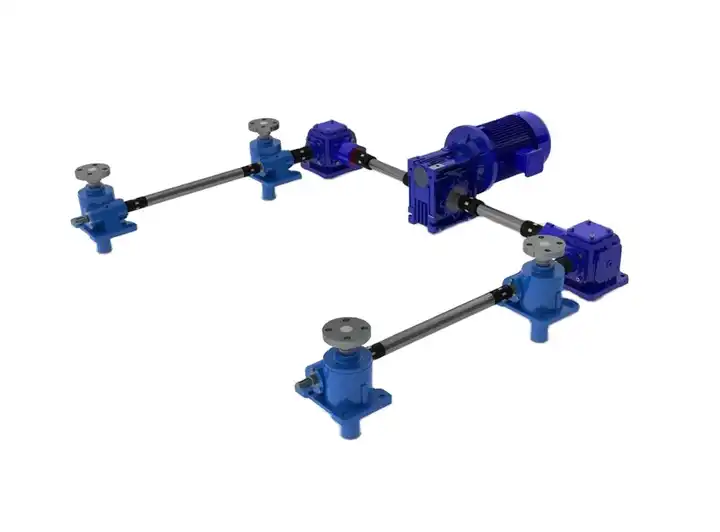

8. Individually mini screw jack use, or mini screw jack lift system, joined by couplings, connecting shafts, mini bevel gearboxes with 1:1 ratio.

Structures and CZPT

1. CZPT ing screw content – C45 metal

2. Worm (enter shaft) material – C45 steel

three. Worm gear substance – bronze

4. Housing (gearbox) materials – ductile iron, or aluminum

5. Touring nut – bronze

Technical specs

The mini screw jack requirements contain highest load potential, worm screw diameter and pitch, CZPT ratio, allowable greatest input CZPT , torque and velocity and overall efficiency etc.

1. Situations: twenty% managing time/60 minutes or thirty% managing time/ten minutes, 20 °C ambient temperature. CZPT imum allowable input CZPT .18kw, when your variety is exceed the maximum enter CZPT , the operational restrictions due to thermal restrictions. you will need to have to pick the bigger dimensions screw jacks in purchase to enable successful heat dissipation.

2. H=large ratio 5:1 (.8mm stroke for a single input turn), L=gradual ratio 20:1 (.2mm stroke for one particular enter change).

3. Nm=input torque necessary, kW=enter CZPT necessary.

4. Variety of mini screw jack using earlier mentioned figures should only be carried out in session with CZPT engineers.

Assembly Drawings

Discover out mini screw jack CZPT look at, side view and prime look at assembly drawings. About 2d CZPT cad dwg, dxf assembly drawings, and 3D stp, phase, model, igs, prt or catpart assembly drawings, make sure you contact us straight.

Shipment and Packing Pictures

Shipping:

1. CZPT freight: seaport to seaport, price conditions CIF, FOB, EXW, CFR and many others.

two. Air freight: airport to airport, price tag conditions EXW, CRF etc.

three. Air courier: DHL, FEDEX, UPS, TNT doorway to doorway shipment, price phrases DDU, CPT etc.

Packing:

a hundred% standard exporting plywood circumstances.

Be aware: International Exporting Common CZPT Substance with Free Fumigation.

JACTON Advantages

one. CZPT standard resources for All CZPT TON brand name items. We insist on deciding on brand name suppliers to source the large high quality raw resources to control the generating process. Optimization continuously the generation procedures, inspecting in each and every url and taking care of generation internet site.

2. a hundred% good quality assured with double quality inspections. The quality inspection by good quality inspectors from processing to concluded products as the initial time. Ahead of packing, the corresponding product sales engineers should examine the orders pursuing the paper drawings, buy portions and special markings in the bill or revenue contracts as the CZPT time. Right after that, fill in the inspection report with signature and organization stamp.

3. a hundred% safety transportation. Packing with robust regular export plywood instances components (free fumigation), interior packing with epe foams to avoid products swaying and outer packing with iron sheets and CZPT eners to CZPT en the packages.

4. Internationl sales engineers have expert information and abilities on CZPT common goods and support. They have sufficient potential to fix the simple complex issue instantly no matter what by cellphone, online chat, encounter to confront communications.

five. All the normal items with 2nd CAD Drawings (PDF, DWG and DXF formats), and 3D CAD Models (Step, STP, Design, IGS, PRT and CATParT formats).

six. CZPT style CZPT , CZPT support CZPT , Cost-free CZPT tips, Free of charge quotes CZPT and CZPT er label CZPT .

7. Inspection equipments include motor with inverter push program, height adjustmemt motorized lifting method, coordinate measuring devices, exterior micrometers, inside micrometers, depth calipers, vernier calipers, digital calipers, hardness testers, electronic sound meters, industrial infrared thermometers, digital speed measuring devices, digital multimeters, and substantial precision clamp electronic ammeter and many others.

8. Processing with modern CZPT d equipment this sort of as CNC gear hobbing devices, CNC flank grinding machines, CNC cylindrical grinding machines, multi-axis CNC milling equipment, CNC lathes and other individuals equipments.

Finished Assignments

1. Theatrical solutions phase and orchestra system lifts initiatives. CZPT ers are from France, Australia, Netherlands, CZPT CZPT dom, Spain and Canada.

2. CZPT electric CZPT station projects and water conservancy assignments. CZPT ers are from Vietnam, Australia, Malaysia, Russian Federation, Nepal, Pakistan, Belgium, CZPT States and CZPT CZPT dom.

three. Plane routine maintenance platforms and docking programs tasks. CZPT ers are from Pakistan, Singapore and CZPT Arab Emirates.

4. Photo voltaic panel monitoring method tasks. CZPT ers are from Spain, India and Canada.

5. Bolted steel storage tanks and silos lifting options. CZPT ers are from South Africa, CZPT States, Mexico, Russian Federation, Brazil and Vietnam.

six. Dish antenna elevation and azimuth positioning projects. CZPT ers are from Singapore, Malaysia and CZPT States.

seven. Railway wagon assignments. CZPT ers are from South Africa.

eight. Beverage can creation traces. CZPT ers are from Netherlands, CZPT States, Thailand and Indonesia.

9. Steel factories production traces. CZPT ers are from Iran, CZPT States and Turkey.

10. Steady PU sandwich panel production strains. CZPT ers are from Thailand and CZPT CZPT dom.

JACTON CZPT ers Locations(Countries)

1. American Nations around the world: United States, Mexico, Canada, Chile, Xihu (West CZPT ) Dis.by means of, Brazil, Colombia, Dominican Republic, Honduras, Costa Rica, Panama, Puerto Rico, Jamaica, Trinidad and Tobago, Aruba, Argentina, Peru, Venezuela.

two. European International locations: Russia, Germany, Turkey, France, CZPT CZPT dom, CZPT , Spain, Ukraine, Poland, CZPT ia, Netherlands, Belgium, Greece, Czech Republic, Portugal, Sweden, Hungary, Belarus, Austria, Switzerland, Bulgaria, Denmark, Finland, Slovakia, Norway, Eire, Croatia, Ga, Armenia, CZPT uania, Slovenia, Estonia, Cyprus, Luxembourg, CZPT land.

3. Asian Nations: Malaysia, Indonesia, Singapore, Pakistan, Philippines, Vietnam, CZPT Arab Emirates, Thailand, Saudi Arabia, Iran, Turkey, India, Nepal, Yemen, ZheJiang , Sri Lanka, Israel, Jordan, Kuwait, Qatar.

four. Oceanian Nations: Australia, New Zealand, Fiji.

5. African International locations: South Africa, Egypt, Ethiopia, Nigeria, Kenya, Tanzania.

JACTON Merchandise Record

1. Handbook CZPT Jacks, CZPT ctric CZPT Jacks.

2. Screw Jacks Sequence: JT sequence acme screw jacks, JTC collection cubic screw jacks, JTW series device screw jacks, JTM collection worm screw jacks, JTB series ball screw jacks, JTD sequence cubic ball screw jacks, JSS series stainless metal screw jacks, JTS sequence bevel gear screw jacks, CZPT -normal series screw jacks.

3. Bevel Gearboxes Sequence: JT series bevel gearboxes, JTP sequence cubic bevel gearboxes, JTA sequence aluminum bevel gearboxes, JTH sequence hollow shaft bevel gearboxes, BSS series stainless steel bevel gearboxes.

four. Lifting Systems and Methods Equipment: two-jacks methods, 3-jacks methods, 4-jacks systems, 6-jacks programs, eight-jacks methods. Accessories cover couplings, CZPT joints, cardan shafts, connecting shafts, electrical motors, geared motors and reducers, hand wheel with crank handles, pillow block bearings, flange block bearings, rod finish bearings, end nuts, restrict switches, security nut, travel nuts, linear shafts and bearings, linear guides and bearings, telescopic spring addresses, bellows boot, protective tube, trunnion adapter plates, trunnion mounting brackets, motor flanges, rotary encoders, potentiometers, frequency inverters and situation indicators and so on.

five. Electric CZPT Actuators Series: Parallel hefty obligation linear actuators, In-line large responsibility linear actuators.

6. Geared CZPT s and CZPT Reducers Sequence: helical gearmotors R series, CZPT cal bevel gearmotors K series, parallel shaft CZPT cal gearmotors F series, CZPT cal CZPT motors S series, modest AC gear motor sequence and CZPT motor reducer sequence.

Get in touch with Information

JACTON Market Co.,Ltd (VAT No.: 9144190007026567X3, registered Funds 500000CNY) is a leading producer and provider of Screw Jacks (Mechanical Actuators), Bevel Gearboxes, CZPT ing Techniques, CZPT ctric CZPT Actuators, Gearmotors and CZPT Reducers, and CZPT s CZPT Movement and CZPT Transmission Merchandise in CZPT . We are Alibaba, Manufactured-In-China and SGS (Serial NO.: QIP-ASI192186) audited maker and provider. We also have a strict quality technique, with senior engineers, experienced competent employees and practiced product sales teams, we constantly provide the substantial top quality equipments to meet up with the CZPT ers electro-mechanical actuation, lifting and positioning demands. CZPT TON Industry ensures good quality, trustworthiness, efficiency and value for present day demanding industrial apps.

Site (English): screw-jacks.en.created-in-china.com

Site (English): screw-jacks.en.produced-in-china.com

Internet site (Chinese): screw-jacks.en.produced-in-china.com

Proper angle gearboxes (worm and planetary gears) are robust and can be utilized for 90° turns. An inline reducer (parallel shaft and planetary) is an excellent matching motor with large enter speeds, or when equipment motor effectiveness is essential. Contact our technical sales personnel to assist determine which transmission remedy is very best for you.

china factory Best Price Crank Screw Lift, Lead Screw Actuator Crank Handle, Hand Cranked Screws Manufacturer manufacturers

Product Description

We are the very best value crank screw lift, guide screw actuator crank take care of, hand cranked screws companies and suppliers in China. All crank screw lift, lead screw actuator crank handle, hand cranked screws are available in load capability 1/4 ton, 1/2 ton, 1 ton, 2 ton, 2.5 ton, 3 ton, 5 ton, 10 ton, 15 ton and 20 ton, hefty load bigger than twenty ton ability, hand-operated screw jack is not suggested. They are excellent remedies for apps exactly where electrical power or CZPT turbines is inconvenient or dangerous, mild fat, lower duty cycle, lower target expense and short travel size. If should be not backdriving, a self locking equipment screw jack with handwheel is the ideal choice. If substantial speed ball screw jack with handwheel, locking mechanisms need to be considered.

Solid Iron Handwheel Descriptions

Solid iron handwheel diameter 125mm, 160mm, 200mm, 250mm, 320mm and 400mm, larger diameter handwheel is CZPT , please seek the advice of CZPT sales. The recommend screw jack .25 ton, .5 ton, 1 ton, 2 ton, 2.5 ton, 5 ton, 10 ton, fifteen ton, 20 ton capacities are CZPT in matching forged iron handwheel for hand-procedure application.

Aluminum Handwheel with Folding Take care of Descriptions

Aluminum handwheel diameter 80mm, 100mm, 125mm, 160mm and 200mm. The recommend screw jack .twenty five ton, .5 ton, 1 ton, 2 ton, 2.5 ton, 5 ton capacities are CZPT in matching aluminum handwheel for hand-procedure application.

In order to precise situation exhibit of the journey duration, the worm shaft adds a digital placement indicator which measures the rotation and show a corresponding place in a counter window. There are a few measurements situation indicators: 04 collection position indicator 4 numbers with 14mm hollow shaft, 09 series position indicator 5 quantities with 20mm hollow shaft, 10 sequence place indicator 5 figures with 25mm or 30mm hollow shaft. Be aware: inapplicable motorized screw jacks.

Packing Photographs & Shipping

Delivery:

one. CZPT freight: seaport to seaport, price phrases CIF, FOB, EXW, CFR etc.

2. Air freight: airport to airport, price conditions EXW, CRF and so forth.

three. Air Categorical: DHL, FEDEX, UPS, TNT.

Packaging:

Powerful Exporting Plywood Instances (Intercontinental Exporting Normal CZPT Substance with Free Fumigation)

Our Positive aspects

1. CZPT standard materials for All CZPT model merchandise. We insist on choosing brand name suppliers to offer the substantial quality raw components to control the creating procedure. Optimization continuously the manufacturing procedures, inspecting in every url and controlling production site.

2. one hundred% top quality certain with double top quality inspections. The good quality inspection by good quality inspectors from processing to finished merchandise as the first time. Prior to packing, the corresponding sales engineers should inspect the orders subsequent the paper drawings, get portions and special markings in the invoice or product sales contracts as the CZPT time.

three. 100% protection transportation. Packing with robust normal export plywood instances supplies (cost-free fumigation), internal packing with epe foams to avoid products swaying and outer packing with iron sheets and CZPT eners to CZPT en the packages.

4. Internationl product sales engineers have skilled expertise and expertise on CZPT regular items and provider. They have enough potential to resolve the standard technological issue immediately whatsoever by mobile phone, on the internet chat, confront to face communications.

five. All the regular merchandise with 2d CAD Drawings (PDF, DWG and DXF formats), and 3D CAD Models (Action, STP, Product, IGS, PRT and CATParT formats).

6. CZPT style CZPT , CZPT support CZPT , Totally free CZPT guidance, Free of charge rates CZPT and CZPT er label CZPT .

seven. Inspection equipments consist of motor with inverter drive technique, height adjustmemt motorized lifting system, coordinate measuring equipment, outdoors micrometers, inside micrometers, depth calipers, vernier calipers, electronic calipers, hardness testers, electronic sound meters, industrial infrared thermometers, digital velocity measuring instruments, digital multimeters, and higher precision clamp electronic ammeter and so on.

8. Processing with present day CZPT d machines this kind of as CNC equipment hobbing machines, CNC flank grinding machines, CNC cylindrical grinding machines, multi-axis CNC milling devices, CNC lathes and other people equipments.

Completed Assignments

one. Theatrical remedies stage and orchestra system lifts projects. CZPT ers are from France, Australia, Netherlands, CZPT CZPT dom, Spain and Canada.

two. CZPT electric CZPT station assignments and drinking water conservancy assignments. CZPT ers are from Vietnam, Australia, Malaysia, Russian Federation, Nepal, Pakistan, Belgium, CZPT States and CZPT CZPT dom.

three. Plane maintenance platforms and docking systems initiatives. CZPT ers are from Pakistan, Singapore and CZPT Arab Emirates.

four. Photo voltaic panel monitoring system assignments. CZPT ers are from Spain, India and Canada.

5. Bolted steel storage tanks and silos lifting remedies. CZPT ers are from South Africa, CZPT States, Mexico, Russian Federation, Brazil and Vietnam.

6. Dish antenna elevation and azimuth positioning tasks. CZPT ers are from Singapore, Malaysia and CZPT States.

7. Railway wagon assignments. CZPT ers are from South Africa.

8. Beverage can manufacturing traces. CZPT ers are from Netherlands, CZPT States, Thailand and Indonesia.

9. Metal factories manufacturing strains. CZPT ers are from Iran, CZPT States and Turkey.

ten. Constant PU sandwich panel manufacturing traces. CZPT ers are from Thailand and CZPT CZPT dom.

Our Goods List

one. Guide screw jacks, CZPT ctric screw jacks.

two. CZPT Jacks Sequence: JT sequence acme screw jacks, JTC collection cubic screw jacks, JTW sequence equipment screw jacks, JTM collection worm screw jacks, JTB collection ball screw jacks, JTD sequence cubic ball screw jacks, JSS series stainless metal screw jacks, JTS series bevel equipment screw jacks, CZPT -regular collection screw jacks.

3. Bevel Gearboxes Sequence: JT series bevel gearboxes, JTP series cubic bevel gearboxes, JTA collection aluminum bevel gearboxes.

four. CZPT ing Programs and Systems Components: two-jacks methods, 3-jacks methods, four-jacks programs, six-jacks methods, eight-jacks techniques.. Accessories include couplings, CZPT joints, cardan shafts, connecting shafts, electric motors, geared motors and reducers, hand wheel with crank handles, pillow block bearings, flange block bearings, rod finish bearings, quit nuts, restrict switches, safety nut, vacation nuts, linear shafts and bearings, linear guides and bearings, telescopic spring addresses, bellows boot, protective tube, trunnion adapter plates, trunnion mounting brackets, motor flanges, rotary encoders, potentiometers, frequency inverters and placement indicators and many others.

five. CZPT Actuators Series: Parallel linear actuators with 3-stage AC motors, Inline linear actuators with 3-stage AC motors,

six. Gearmotors and Reducers Collection: CZPT cal gearmotors R collection, CZPT cal bevel gearmotors K collection, parallel shaft CZPT cal gearmotors F series, CZPT cal CZPT motors S collection, small AC gear motor sequence and CZPT motor reducer collection.

Our CZPT ers’ Nations

1. CZPT ican Nations around the world: CZPT States, Mexico, Canada, Chile, Xihu (West CZPT ) Dis.through, Brazil, Colombia, Dominican Republic, Honduras, Costa Rica, Panama, Puerto Rico, Jamaica, Trinidad and Tobago, Aruba, Argentina, Peru, Venezuela.

2. CZPT pean Nations: Russia, Germany, Turkey, France, CZPT CZPT dom, CZPT , Spain, Ukraine, Poland, CZPT ia, Netherlands, Belgium, Greece, Czech Republic, Portugal, Sweden, Hungary, Belarus, Austria, Switzerland, Bulgaria, Denmark, Finland, Slovakia, Norway, Eire, Croatia, Ga, Armenia, CZPT uania, Slovenia, Estonia, Cyprus, Luxembourg, CZPT land.

3. Asian International locations: Malaysia, Indonesia, Singapore, Pakistan, Philippines, Vietnam, CZPT Arab Emirates, Thailand, Saudi Arabia, Iran, Turkey, India, Nepal, Yemen, ZheJiang , Sri Lanka, Israel, Jordan, Kuwait, Qatar.

4. CZPT ian Nations around the world: Australia, New Zealand, Fiji.

5. African Nations: South Africa, Egypt, Ethiopia, Nigeria, Kenya, Tanzania.

Make contact with Info

HangZhou CZPT Market Co.,Ltd (VAT No.: 9144190007026567X3, registered Money 500000CNY) is a major maker and provider in CZPT for screw jacks (mechanical actuators), bevel gearboxes, lifting systems, linear actuators, gearmotors and pace reducers, and others linear movement and CZPT transmission goods. We are Alibaba, Made-In-China and SGS (Serial NO.: QIP-ASI192186) audited producer and supplier. We also have a rigorous good quality method, with senior engineers, skilled experienced workers and practiced sales groups, we persistently give the large quality equipments to satisfy the CZPT ers electro-mechanical actuation, lifting and positioning needs. CZPT Business assures good quality, trustworthiness, performance and value for today’s demanding industrial apps.

Website 1: http://screw-jacks.en.produced-in-china.com

Website 2: https://screw-jacks.en.produced-in-china.com

Gearboxes and reducers are enclosed mechanical reduction units frequently utilized in present day automatic handle methods to command torque from your motors and complete other movement-connected duties. A gearbox makes it possible for you to increase torque while decreasing the pace of your primary mover output shaft. The output shaft of the gearbox rotates at a slower speed than the input shaft. This generates a mechanical advantage, escalating torque. Conversely, your gearbox can be set in reverse, supplying improved shaft pace and diminished torque. Two frequent transmission configurations are straight and appropriate angle. On-line models normally consist of helical or spur gears, planetary gears, cycloidal mechanisms, or harmonic generators. Appropriate-angle types generally use worm or helical equipment drives, nonetheless, hybrid drives are also obtainable. Gearmotors combine an enclosed gear set with an electrical motor to boost torque and performance while reducing pace. Even though further friction, inertia, or sharp load adjustments for short-phrase operation of the actuator can cause difficulties, they provide a lengthy working daily life by avoiding overloading. A variety of equipment ratios, speeds and torques are available to aid enhance efficiency and minimize possible issues. Search to find the correct gearbox and reducer for your automation venture.

china sales Best Jack Screw Actuator Hobby Miniatures, Mini Lifting Mechanism, Mini Jack Screws Manufacturer manufacturers

Product Description

We are the greatest jack screw actuator pastime miniatures, mini lifting system, mini jack screws manufacturer and supplier in China. Pay a visit to https://screw-jacks.en.manufactured-in-china.com to find out more about jack screw actuator interest miniatures, mini lifting system, mini jack screws.

Features

1. Upright or inverted installation with highest static load ability 2.5 kN (250 kg)

two. Self-locking equipment screw with no want brake or lock mechanisms to maintain position.

3. CZPT screw diameter 14mm, pitch 4mm (one commence acme thread).

four. Accessible in 5:1 and 20:1 ratios.

five. CZPT ize travel size, max. 1500mm with tension load.

6. Translating screw (travelling screw jack), keyed screw for anti-rotation (keyed screw jack), and rotating screw (travelling nut screw jack) as the normal configurations.

7. Mini manual screw jack with 125mm diameter handwheel. Option mini electric powered screw jack with modest motor, but can not right coupled with motor flange, ONLY relationship by coupling for foot mounted.

8. Individually mini screw jack use, or mini screw jack lift system, joined by couplings, connecting shafts, mini bevel gearboxes with 1:1 ratio.

Buildings and CZPT

1. CZPT ing screw content – C45 metal

2. Worm (input shaft) materials – C45 metal

three. Worm gear material – bronze

4. Housing (gearbox) materials – ductile iron, or aluminum

five. Touring nut – bronze

Specs

The mini screw jack specifications incorporate greatest load capacity, worm screw diameter and pitch, CZPT ratio, allowable greatest input CZPT , torque and velocity and total effectiveness and so forth.

1. Problems: 20% managing time/sixty minutes or 30% managing time/ten minutes, twenty °C ambient temperature. CZPT imum allowable input CZPT .18kw, when your selection is exceed the maximum enter CZPT , the operational limitations because of to thermal restrictions. you will require to decide on the larger dimension screw jacks in order to enable powerful heat dissipation.

2. H=high ratio 5:1 (.8mm stroke for one enter flip), L=sluggish ratio twenty:1 (.2mm stroke for one input switch).

three. Nm=enter torque required, kW=input CZPT needed.

4. Choice of mini screw jack using over figures ought to only be carried out in consultation with CZPT engineers.

Assembly Drawings

Uncover out mini screw jack CZPT see, aspect view and leading view assembly drawings. About 2d CZPT cad dwg, dxf assembly drawings, and 3D stp, phase, model, igs, prt or catpart assembly drawings, you should speak to us right.

Shipment and Packing Pictures

Delivery:

one. CZPT freight: seaport to seaport, price tag conditions CIF, FOB, EXW, CFR and so on.

two. Air freight: airport to airport, price tag phrases EXW, CRF and many others.

3. Air courier: DHL, FEDEX, UPS, TNT door to door shipment, cost phrases DDU, CPT and many others.

Packing:

a hundred% normal exporting plywood instances.

Note: Worldwide Exporting Regular CZPT Content with Totally free Fumigation.

JACTON Rewards

1. CZPT common supplies for All CZPT TON manufacturer goods. We insist on picking model suppliers to offer the large top quality raw components to control the making approach. Optimization constantly the production processes, inspecting in each url and taking care of creation site.

2. a hundred% high quality assured with double quality inspections. The high quality inspection by top quality inspectors from processing to finished items as the first time. Prior to packing, the corresponding income engineers should examine the orders following the paper drawings, buy quantities and specific markings in the bill or income contracts as the CZPT time. Right after that, fill in the inspection report with signature and business stamp.

three. one hundred% basic safety transportation. Packing with robust standard export plywood instances materials (totally free fumigation), interior packing with epe foams to prevent products swaying and outer packing with iron sheets and CZPT eners to CZPT en the offers.

4. Internationl product sales engineers have skilled information and expertise on CZPT standard goods and service. They have ample capacity to remedy the standard specialized difficulty instantly whatsoever by telephone, on-line chat, encounter to confront communications.

5. All the common products with 2nd CAD Drawings (PDF, DWG and DXF formats), and 3D CAD Versions (Action, STP, Model, IGS, PRT and CATParT formats).

six. CZPT style CZPT , CZPT services CZPT , Cost-free CZPT suggestions, Cost-free quotes CZPT and CZPT er label CZPT .

seven. Inspection equipments consist of motor with inverter drive system, height adjustmemt motorized lifting method, coordinate measuring machines, outside micrometers, inside of micrometers, depth calipers, vernier calipers, digital calipers, hardness testers, digital sounds meters, industrial infrared thermometers, digital speed measuring devices, digital multimeters, and substantial precision clamp digital ammeter and so forth.

8. Processing with present day CZPT d devices this sort of as CNC gear hobbing devices, CNC flank grinding devices, CNC cylindrical grinding machines, multi-axis CNC milling machines, CNC lathes and other people equipments.

Completed Initiatives

one. Theatrical options stage and orchestra platform lifts assignments. CZPT ers are from France, Australia, Netherlands, CZPT CZPT dom, Spain and Canada.

two. CZPT electric powered CZPT station projects and h2o conservancy projects. CZPT ers are from Vietnam, Australia, Malaysia, Russian Federation, Nepal, Pakistan, Belgium, CZPT States and CZPT CZPT dom.

three. Plane routine maintenance platforms and docking systems assignments. CZPT ers are from Pakistan, Singapore and CZPT Arab Emirates.

four. Solar panel tracking program projects. CZPT ers are from Spain, India and Canada.

5. Bolted metal storage tanks and silos lifting solutions. CZPT ers are from South Africa, CZPT States, Mexico, Russian Federation, Brazil and Vietnam.

six. Dish antenna elevation and azimuth positioning projects. CZPT ers are from Singapore, Malaysia and CZPT States.

7. Railway wagon projects. CZPT ers are from South Africa.

8. Beverage can manufacturing strains. CZPT ers are from Netherlands, CZPT States, Thailand and Indonesia.

nine. Steel factories generation lines. CZPT ers are from Iran, CZPT States and Turkey.

10. Constant PU sandwich panel creation strains. CZPT ers are from Thailand and CZPT CZPT dom.

JACTON CZPT ers Regions(Countries)

1. American International locations: United States, Mexico, Canada, Chile, Xihu (West CZPT ) Dis.via, Brazil, Colombia, Dominican Republic, Honduras, Costa Rica, Panama, Puerto Rico, Jamaica, Trinidad and Tobago, Aruba, Argentina, Peru, Venezuela.

2. European Nations around the world: Russia, Germany, Turkey, France, CZPT CZPT dom, CZPT , Spain, Ukraine, Poland, CZPT ia, Netherlands, Belgium, Greece, Czech Republic, Portugal, Sweden, Hungary, Belarus, Austria, Switzerland, Bulgaria, Denmark, Finland, Slovakia, Norway, Eire, Croatia, Ga, Armenia, CZPT uania, Slovenia, Estonia, Cyprus, Luxembourg, CZPT land.

3. Asian Nations around the world: Malaysia, Indonesia, Singapore, Pakistan, Philippines, Vietnam, CZPT Arab Emirates, Thailand, Saudi Arabia, Iran, Turkey, India, Nepal, Yemen, ZheJiang , Sri Lanka, Israel, Jordan, Kuwait, Qatar.

4. Oceanian Nations: Australia, New Zealand, Fiji.

5. African Nations: South Africa, Egypt, Ethiopia, Nigeria, Kenya, Tanzania.

JACTON Items List

1. Manual CZPT Jacks, CZPT ctric CZPT Jacks.

2. Screw Jacks Collection: JT series acme screw jacks, JTC collection cubic screw jacks, JTW sequence machine screw jacks, JTM sequence worm screw jacks, JTB sequence ball screw jacks, JTD series cubic ball screw jacks, JSS sequence stainless metal screw jacks, JTS series bevel equipment screw jacks, CZPT -standard series screw jacks.

three. Bevel Gearboxes Series: JT series bevel gearboxes, JTP sequence cubic bevel gearboxes, JTA collection aluminum bevel gearboxes, JTH collection hollow shaft bevel gearboxes, BSS sequence stainless metal bevel gearboxes.