Product Description

Product Description

Product Name: Nonstandard CNC Machining Turning 304 316 Stainless Steel Shafts

Company Name: HangZhou CHINAMFG Hardware Industry Co., Ltd.

Keywords: Shaft, Custom Precision Shaft, Precision Shaft, CNC Parts Screw, Special Screw, Stainless Steel Screws, Screw, Custom Stainless Steel Screw, Stainless Steel Screw Bolts, 316 Stainless Steel Screws, 316L Stainless Steel Screw, 304 Stainless Steel Screw, Screw Stainless Steel 316, Custom Screws Stainless, Stainless Steel Screws, Steel Screw Stainless, Screw Stainless Steel, Head Screw Stainless, 316 Steel Screws, Custom Shaft

Attributes: Material: Carbon Steel, Load: Drive Shaft, Stiffness / Rigid Axle

Description: Explore our range of nonstandard CNC machining turning stainless steel shafts. Made from high-quality 304 and 316 stainless steel, these custom precision shafts offer exceptional strength and durability. Perfect for various applications, including drive shafts, these shafts provide stiffness and rigidity. Choose from a wide selection of sizes and designs to meet your specific needs. Trust HangZhou CHINAMFG Hardware Industry Co., Ltd. for reliable and precise CNC parts.

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, AL6082-T6 etc. |

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | mild steel, Carbon steel,12L14, 12L15,4140, 4340, Q235, Q345B, 20#, 45# etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H58,H68, H80, H90 etc. |

| Copper | C11000,C12000,C12000 C36000 etc. |

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, PP,PEI, Peek etc. |

Nonstandard CNC Machining Turning Stainless Steel Shafts

Looking for custom precision shafts? Our stainless steel screws are made from high-quality 304 and 316 stainless steel. With a rigid axle and excellent stiffness, these shafts are perfect for drive shaft applications. Order your custom shafts today!

| Aluminum parts | Stainless Steel parts | Steel parts | Brass parts |

| Clear Anodized | Polishing | Zinc plating | Nickel plating |

| Color Anodized | Passivating | Nickel plating | chrome plating |

| Sandblast Anodized | Sandblasting | Chrome plating | Electrophoresis black |

| Polishing | Laser engraving | Oxide black | Oxide black |

| Brushing | Electrophoresis black | Carburized | Powder coated |

| Chroming | Oxide black | Heat treatment | |

| Chemical Film | Powder Coated |

Company Profile

JIESHENG Hardware – Precision CNC Spare Parts

JIESHENG Hardware, a leading manufacturer in the industry, specializes in the production of precision CNC lathes, automatic lathe parts, precision non-standard parts, rivets and nuts, washers, stamping parts, and more. Our expertise lies in providing high-quality non-standard metal parts to clients in various industries.

Our products are made from a wide range of materials including stainless steel, copper, brass, bronze, iron, aluminum, and various types of steel. This versatility allows us to cater to the specific needs of industries such as electronics, hardware, lighting, toys, sanitary ware, furniture, medical, sports equipment, and more.

Product Details

Product Name: Brass Insert Sharp Knurl Nuts for Thermoplastics

Before requesting a quotation, please provide us with the following information:

- Size drawing (If unavailable, please provide detailed product size and picture)

- Material (Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc, etc.)

- Quantity (Higher quantities may result in better pricing)

- Surface treatment (Polishing, Anodize, Nickel, Zinc, Tin, Chrome, Silver plating, etc.)

- Hardness

- Packing Term

If you are interested in brass tubular rivets, please feel free to contact us.

Contact Person: Alice Lee

Company: HangZhou CHINAMFG Hardware Industry Co., Ltd.

FAQ

Stainless Steel Dowel Pins

Are you in need of stainless steel dowel pins for your manufacturing needs? Look no further! HangZhou CHINAMFG Hardware Industry Co., Ltd. is here to provide you with high-quality dowel pins that meet your requirements.

Features:

- Made from durable stainless steel material

- Precision machined for accurate dimensions

- Available in various sizes and lengths

- Corrosion-resistant for long-lasting performance

Benefits:

- Ensures secure and reliable connections

- Reduces the risk of misalignment

- Increases the strength and stability of assembled parts

- Can withstand high temperatures and harsh environments

Sample Request:

If you would like to request a sample of our stainless steel dowel pins, simply contact us and provide the necessary details. We may require a sample cost, but it will be refunded once you proceed with a mass production order. In special conditions, we also offer free samples.

Lead Time:

The lead time for your order depends on the quantity. Generally, it takes 7-20 days after order confirmation for us to fulfill your requirements.

Urgent Orders:

If you have urgent manufacturing needs, don’t worry! We will do our best to assist you. As we have our own factory, we can be flexible in adjusting our production schedule to accommodate your urgent requests.

Confidentiality:

We understand the importance of keeping your designs confidential. If you require a non-disclosure agreement (NDA), we are more than willing to CHINAMFG it. Rest assured that we will not display or share your designs with anyone.

Production Updates:

Even if you can’t visit our factory, we will keep you informed about the production process. We will provide you with a detailed production schedule and send pictures and videos showcasing the machining progress.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

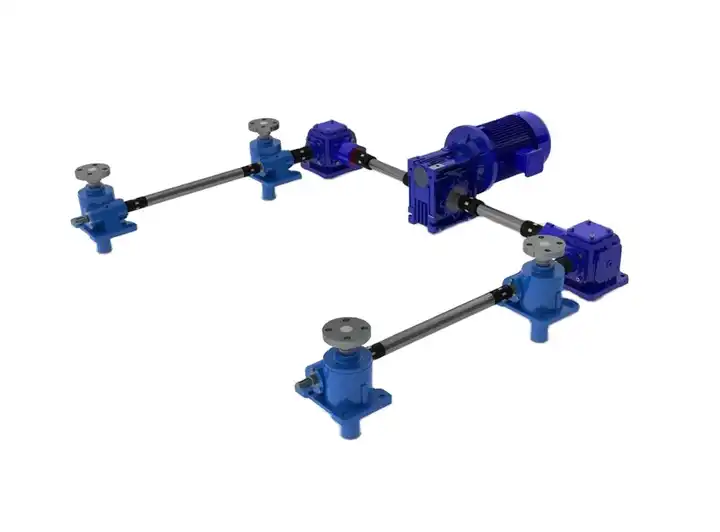

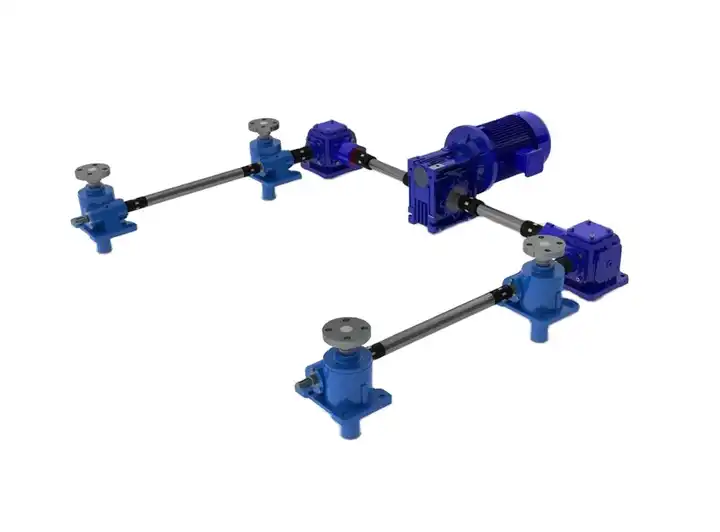

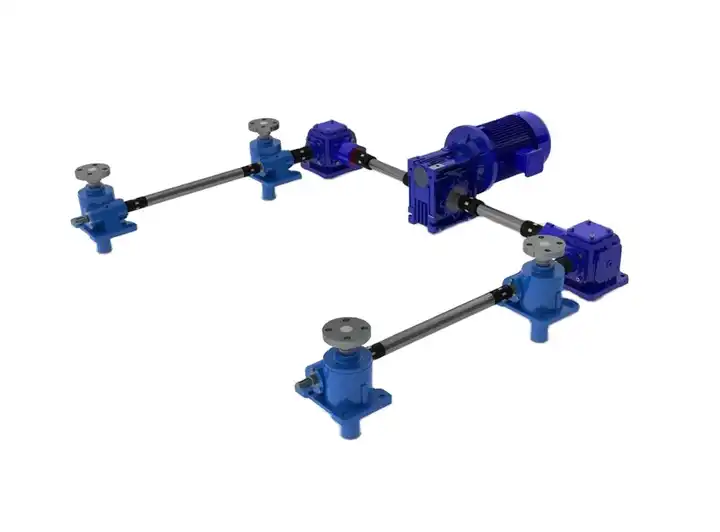

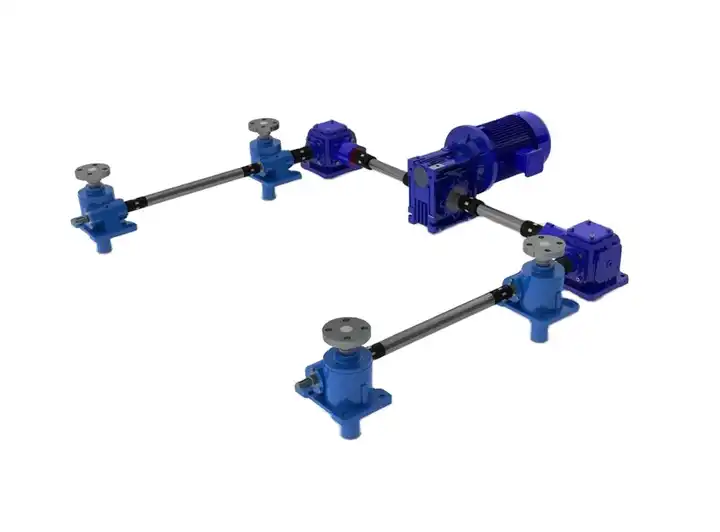

What advancements in screw jack technology have improved efficiency and reliability?

Advancements in screw jack technology have led to significant improvements in efficiency and reliability. Here are some key advancements that have contributed to these improvements:

- High-Efficiency Ball Screws: Traditional screw jacks often used trapezoidal or square threads, which had relatively lower efficiency due to higher friction. However, the introduction of high-efficiency ball screws in screw jack designs has greatly improved efficiency. Ball screws offer low friction and higher efficiency, resulting in reduced power consumption and improved overall system efficiency.

- Improved Lubrication Systems: Proper lubrication is crucial for the smooth operation and longevity of screw jacks. Advancements in lubrication systems, such as the use of self-lubricating materials, improved lubricants, and better sealing mechanisms, have enhanced the reliability and maintenance intervals of screw jacks. These advancements minimize wear, reduce friction, and ensure consistent performance over extended periods.

- Materials and Coatings: The use of advanced materials and coatings has significantly improved the durability and reliability of screw jacks. Components made from high-strength alloys, such as stainless steel or hardened steel, can withstand higher loads and resist wear. Additionally, coatings like zinc plating or epoxy coatings provide corrosion resistance, extending the lifespan of screw jacks in challenging environments.

- Integrated Sensors and Feedback Systems: Integration of sensors and feedback systems in screw jacks has improved their reliability and control. Position sensors, load sensors, and torque sensors can be integrated into screw jacks to provide real-time feedback and monitoring. This enables precise positioning, load measurement, and the ability to detect and respond to abnormal operating conditions, ensuring safe and reliable operation.

- Automation and Control Integration: The integration of screw jacks with advanced automation and control systems has improved efficiency and reliability. Motorized screw jacks can be integrated with programmable logic controllers (PLCs) or computer numerical control (CNC) systems, enabling precise and synchronized movements, remote operation, and automation. This integration minimizes human error, enhances repeatability, and optimizes the overall efficiency of screw jack systems.

- Design Optimization: Advancements in computer-aided design (CAD) and simulation tools have allowed for the optimization of screw jack designs. Finite element analysis (FEA) and virtual prototyping enable the evaluation and refinement of various design parameters, resulting in improved load-bearing capabilities, reduced weight, and enhanced structural integrity. These design optimizations contribute to increased efficiency and reliability.

These advancements in screw jack technology have collectively improved efficiency, reliability, and overall performance. Manufacturers continue to innovate and refine screw jack designs to meet the evolving needs of various industries, ensuring that screw jacks remain a reliable and efficient solution for lifting and adjusting loads.

How do screw jacks enhance the efficiency of tasks like machinery assembly?

Screw jacks play a significant role in enhancing the efficiency of tasks like machinery assembly. They offer several advantages that contribute to smoother and more efficient assembly processes. Here are some ways in which screw jacks enhance efficiency:

- Precise Positioning: Screw jacks provide precise and controlled positioning, allowing for accurate alignment and assembly of machine components. The threaded screw mechanism enables incremental adjustments, enabling precise positioning and alignment during the assembly process. This precision helps ensure that components fit together correctly, reducing the need for rework or adjustments after assembly.

- Flexible Lifting and Lowering: Screw jacks allow for controlled lifting and lowering of heavy machine components during assembly. By adjusting the screw jack’s height, operators can position the components at the desired elevation, making it easier to align and attach them. The ability to fine-tune the lifting and lowering process enhances efficiency by reducing manual effort and simplifying the assembly tasks.

- Load Distribution: Screw jacks distribute the load evenly across multiple jacks or support points, providing stability during machinery assembly. This load distribution helps prevent excessive stress on individual components and ensures that the weight is properly supported. By maintaining stability and load distribution, screw jacks contribute to efficient and safe assembly processes.

- Height Adjustment: Screw jacks allow for height adjustment of machinery during assembly, enabling operators to align components at the optimal working height. This adjustability is particularly beneficial when assembling large or complex machinery, as it provides ergonomic advantages for the operators. Working at the correct height reduces fatigue and improves productivity, ultimately enhancing the efficiency of the assembly process.

- Modularity and Versatility: Screw jacks are often designed with modularity in mind, allowing them to be easily integrated into various assembly setups. They can be combined with other components such as mounting plates, couplings, or motorized systems to create customized assembly solutions. This modularity and versatility enable efficient adaptation to different assembly requirements and facilitate the integration of screw jacks into existing assembly processes.

- Automation Integration: Screw jacks can be integrated into automated assembly systems, improving efficiency by reducing manual labor and increasing the speed of assembly processes. With appropriate motorization and control systems, screw jacks can be synchronized and operated in conjunction with other automated machinery, streamlining the assembly workflow and reducing cycle times.

By providing precise positioning, flexible lifting and lowering, load distribution, height adjustment, modularity, versatility, and automation integration, screw jacks significantly enhance the efficiency of tasks like machinery assembly. They contribute to smoother operations, improved productivity, and better overall assembly quality.

What is a screw jack and how is it used in various applications?

A screw jack is a mechanical device that converts rotational motion into linear motion. It consists of a threaded shaft (screw) and a nut that engages with the screw. When the screw is rotated, it moves the nut along the screw’s threads, causing linear displacement. Screw jacks are commonly used in various applications where heavy loads need to be lifted, lowered, or positioned with precision. Here are some key points regarding screw jacks and their applications:

- Principle of Operation: Screw jacks operate based on the principle of linear motion generated by the rotary motion of the screw. When the screw is rotated using a handle, motor, or other power source, the nut moves along the screw’s threads, resulting in linear displacement. The pitch of the screw determines the distance traveled per revolution.

- Lifting and Lowering Heavy Loads: Screw jacks are frequently used for lifting and lowering heavy loads in various industries. They provide a mechanical advantage, allowing operators to exert relatively low force to move substantial loads vertically. Screw jacks are commonly used in applications such as automotive lifts, industrial machinery, stage rigging, and construction equipment.

- Precision Positioning: Screw jacks are capable of precise positioning due to their ability to control linear displacement. By accurately controlling the rotational motion of the screw, the nut can be moved with high precision, enabling precise positioning of loads or equipment. This makes screw jacks suitable for applications that require fine adjustments, such as in assembly lines, testing equipment, or positioning systems.

- Load Capacity: Screw jacks are designed to handle a wide range of load capacities, from relatively light loads to extremely heavy loads. The load capacity of a screw jack depends on factors such as the diameter and pitch of the screw, the material and design of the components, and the mechanical arrangement of the jack. Specialized screw jacks can be engineered to handle loads ranging from a few kilograms to several hundred tons.

- Multiple Jack Systems: In applications that require lifting or moving exceptionally heavy loads or to distribute the load evenly, multiple screw jacks can be used in a synchronized arrangement. By mechanically linking several screw jacks together, they can be operated simultaneously to ensure coordinated and balanced lifting or lowering of the load.

- Automation and Motorization: While manual operation using a handle is common for smaller loads, larger and more complex applications often utilize motorized or automated systems. Electric motors, hydraulic systems, or pneumatic systems can be integrated with screw jacks to provide power and control for lifting or positioning operations. This enables efficient and precise operation, especially in industrial or automated processes.

Screw jacks are versatile mechanical devices used for lifting, lowering, and positioning heavy loads with precision. Their applications range from simple manual operations to complex automated systems, making them indispensable in various industries that require controlled linear motion and load handling.

editor by Dream 2024-04-29

Professional

How do screw jacks ensure controlled and synchronized movement in multi-jack systems?

Screw jacks are capable of ensuring controlled and synchronized movement in multi-jack systems through various mechanisms and techniques. These systems are commonly used in applications where multiple screw jacks need to work together to lift or position a load. Here’s how screw jacks achieve controlled and synchronized movement in multi-jack systems:

- Mechanical Synchronization: Screw jacks can be mechanically linked in a multi-jack system to ensure synchronized movement. This can be achieved through the use of rigid couplings, connecting rods, or gear mechanisms that interconnect the input shafts of individual screw jacks. As a result, when one screw jack is operated to lift or lower the load, the mechanical linkage transfers the motion to the other screw jacks, causing them to move in sync. This ensures that all jacks contribute proportionally to the load and maintain a consistent lifting height.

- Electrical Synchronization: In addition to mechanical synchronization, screw jacks can also be electrically synchronized in multi-jack systems. This is typically achieved through the use of motorized screw jacks controlled by a centralized control system. Each motorized screw jack is equipped with position sensors or encoders that provide feedback on their current position. The control system receives this feedback and adjusts the motor speed and direction for each screw jack to ensure synchronized movement. Electrical synchronization enables precise control and allows for adjustments to be made dynamically, compensating for any variations in load distribution or environmental conditions.

- Load Sharing Mechanisms: In multi-jack systems, load sharing mechanisms can be employed to distribute the weight evenly among the screw jacks. Load sharing mechanisms can include load sensors or load cells that measure the individual loads on each jack. The control system then adjusts the lifting force applied by each screw jack to ensure equal distribution of the load. This prevents overloading of any individual jack and promotes balanced movement in the system.

- Position Feedback and Control: Screw jacks in multi-jack systems can be equipped with position feedback devices, such as linear encoders or limit switches, that provide information on the position of the load. This feedback is used by the control system to precisely control the movement of the screw jacks, ensuring that they reach and maintain the desired positions. By continuously monitoring the position feedback, the control system can make adjustments to keep the jacks synchronized and maintain the desired level of control.

- Control System Integration: A centralized control system can be used to integrate and coordinate the operation of multiple screw jacks in a multi-jack system. This control system can utilize programmable logic controllers (PLCs) or computer numerical control (CNC) systems to manage the movement, synchronization, and safety aspects of the screw jacks. The control system enables precise control, real-time monitoring, and the implementation of safety features, enhancing the overall performance and reliability of the multi-jack system.

By employing these mechanisms and techniques, screw jacks ensure controlled and synchronized movement in multi-jack systems. These systems find applications in various industries, such as heavy lifting, material handling, and industrial automation, where precise positioning and synchronized operation are critical requirements.

Can screw jacks be customized or integrated into larger systems for specific uses?

Yes, screw jacks can be customized or integrated into larger systems to meet specific requirements and applications. Their modular nature and versatility allow for various customization and integration possibilities. Here are some ways screw jacks can be customized or integrated into larger systems:

- Load Capacity Customization: Screw jacks can be customized to handle specific load capacities. Manufacturers can design and manufacture screw jacks with different load ratings to accommodate the requirements of a particular application. By customizing the load capacity, screw jacks can be optimized for lifting and supporting a wide range of loads, from light loads in precision applications to heavy machinery in industrial settings.

- Mounting and Connection Options: Screw jacks can be customized to have different mounting and connection options. This allows for seamless integration into existing systems or specific applications. Manufacturers can provide various mounting configurations, such as flange mounts, base mounts, trunnion mounts, or clevis ends, to ensure easy installation and compatibility with the surrounding equipment or structures.

- Stroke Length Customization: The stroke length of a screw jack can be customized to suit specific requirements. The stroke length refers to the distance the lifting screw travels during the jack’s operation. By customizing the stroke length, screw jacks can be tailored to the required vertical movement or extension needed in a particular application. This customization ensures optimal performance and efficiency in lifting or positioning tasks.

- Specialized Materials and Coatings: Screw jacks can be customized with specialized materials or coatings to enhance their performance in specific environments. For example, in corrosive or harsh conditions, screw jacks can be manufactured using corrosion-resistant materials such as stainless steel or coated with protective finishes. This customization ensures the longevity and reliability of screw jacks in demanding applications.

- Integration with Motorized Systems: Screw jacks can be integrated with motorized systems to automate the lifting and positioning processes. By adding electric or hydraulic motorization, screw jacks can be controlled and synchronized with other components or systems, providing precise and automated operations. This integration enables efficient and programmable movements, reducing manual labor and increasing productivity.

- Control and Monitoring Integration: Screw jacks can be integrated with control and monitoring systems for enhanced functionality and safety. By incorporating sensors, limit switches, or feedback mechanisms, screw jacks can provide real-time feedback on position, load, or other parameters. This integration allows for accurate control, monitoring, and protection of the screw jack and the larger system it is a part of.

The customization and integration options for screw jacks make them highly adaptable to specific uses and applications. Manufacturers often work closely with customers to understand their requirements and provide tailored solutions that optimize the performance, efficiency, and reliability of screw jacks within larger systems.

How do screw jacks ensure stable and controlled movement of loads?

Screw jacks are designed to ensure stable and controlled movement of loads through various mechanisms and features. These mechanisms work together to provide stability, precision, and safety during load handling. Here’s how screw jacks achieve stable and controlled movement:

- Self-Locking Mechanism: Screw jacks are equipped with self-locking mechanisms that prevent the load from lowering or descending when the screw is not being rotated. This mechanism ensures that the load remains stable and stationary even in the absence of an external driving force. The self-locking feature is achieved through the thread design and the friction between the screw and the nut. It provides inherent stability and eliminates the need for additional braking or locking mechanisms.

- High Mechanical Advantage: Screw jacks offer a high mechanical advantage, allowing for controlled movement of heavy loads with relatively low input force. The mechanical advantage is determined by the pitch of the screw and the size of the input device. By increasing the pitch or using a larger input device, the mechanical advantage can be enhanced, enabling precise and controlled movement even with substantial loads.

- Precision Thread Design: The threads of the screw and the nut in screw jacks are precision-designed to minimize backlash and play, ensuring smooth and accurate movement. The thread design influences the amount of axial movement achieved per rotation of the screw, directly impacting the precision of load positioning. By using high-quality threads and incorporating anti-backlash features, screw jacks maintain stability and control during load movement.

- Limit Switches and Position Sensors: Screw jacks can be equipped with limit switches or position sensors to provide accurate position feedback and prevent overtravel or exceedance of specified limits. These devices ensure that the load stops at the desired position and prevent any unsafe or unintended movement. Limit switches and position sensors enhance the control and safety of screw jack systems.

- Additional Safety Features: Screw jacks may incorporate additional safety features to ensure stable and controlled movement. These features can include overload protection mechanisms that prevent excessive loads from damaging the screw jack or the load-bearing structure. Emergency stop options or mechanical brakes may also be included to halt the movement in case of emergencies or power failure.

- Sturdy Construction: Screw jacks are built with robust materials and construction to withstand heavy loads and provide stability during operation. The components are designed to handle the forces exerted during load movement and maintain structural integrity. Sturdy construction ensures that the screw jack can reliably handle the load without compromising stability or control.

By incorporating self-locking mechanisms, high mechanical advantage, precision thread design, limit switches, position sensors, additional safety features, and sturdy construction, screw jacks ensure stable and controlled movement of loads. These features work together to provide precise positioning, prevent unintended movement, and enhance the safety of load handling operations.

editor by Dream 2024-04-29

China manufacturer Bicycle Shafts High Quality CNC Turning Stainless Steel Part Custom Metal Shaft Axle Screws Alloy Steel Shafts wheel and axle

Product Description

Key attributes of Customized CNC Machining High Precise transmission Steel Large Spline Gear Shaft

Industry-specific attributes of Customized CNC Machining High Precise transmission Steel Large Spline Gear Shaft

| CNC Machining or Not | Cnc Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys |

Other attributes of Customized CNC Machining High Precise transmission Steel Large Spline Gear Shaft

| Place of Origin | ZheJiang , China |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM |

| Model Number | OEM |

| Brand Name | OEM |

| Material | Metal |

| Process | Cnc Machining+deburrs |

| Surface treatment | Customer’s Request |

| Equipment | CNC Machining Centres / Core moving machine / precision lathe / Automatic loading and unloading equipment |

| Processing Type | Milling / Turning / Stamping |

| OEM/ODM | OEM & ODM CNC Milling Turning Machining Service |

| Drawing Format | 2D/(PDF/CAD)3D(IGES/STEP) |

| Our Service | OEM ODM Customers’drawing |

| Materials Avaliable | Stainless Steel / Aluminum / Metals / Copper / Plastic |

Best Seller of 304 Stainless Steel Polishing Finishing CNC Machining Bracket for Laser Cutting

About YiSheng

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center, CNC Lathe, precision lathe |

| Automatic loading and unloading equipment | |

| Core moving machine | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.001mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Test Equipment | Complete test lab with Projector, High-low temperature test chamber, Tensile tester Gauge, Salt fog test |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC center work range: 510mm*850mm*500mm | |

| Core moving machine work range: φ32mm*85mm | |

| Gerenal Tolerance: (+/-mm) |

CNC Machining: 0.005 |

| Core moving: 0.005 | |

| Turning: 0.005 | |

| Grinding(Flatness/in2): 0.003 | |

| ID/OD Grinding: 0.002 | |

| Wire-Cutting: 0.002 |

RFQ of Customized CNC Machining High Precise transmission Steel Large Spline Gear Shaft /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001 |

|---|---|

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized: | Customized |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can screw jacks be integrated with advanced monitoring and feedback systems?

Yes, screw jacks can be integrated with advanced monitoring and feedback systems to enhance their functionality, control, and safety. The integration of monitoring and feedback systems allows for real-time data acquisition, analysis, and precise control over the operation of screw jacks. Here’s how screw jacks can be integrated with advanced monitoring and feedback systems:

- Sensors and Load Cells: Sensors and load cells can be installed in screw jacks to measure parameters such as force, torque, displacement, or position. These sensors provide real-time feedback on the performance and condition of the screw jack, allowing for precise control and monitoring of the applied load or position.

- Position Encoders: Position encoders can be used to measure the position and movement of the screw jack accurately. By integrating position encoders, the exact position of the screw jack can be monitored and controlled, enabling precise positioning and automation in various applications.

- Control Systems: Advanced control systems, such as programmable logic controllers (PLCs) or computer numerical control (CNC) systems, can be connected to screw jacks. These control systems receive data from the sensors and load cells and use algorithms to calculate the required input commands for the screw jacks. By integrating control systems, precise and automated control over the screw jacks can be achieved.

- Human-Machine Interface (HMI): HMIs can be used to provide operators with a user-friendly interface to monitor and control the screw jacks. Through an HMI, operators can visualize real-time data, set parameters, and make adjustments as needed. This enhances the ease of operation and allows for efficient monitoring and control of the screw jacks.

- Data Logging and Analysis: Integration with advanced monitoring and feedback systems enables the collection and logging of data from the screw jacks. This data can be analyzed to identify patterns, trends, or anomalies, providing insights into the performance, efficiency, and maintenance requirements of the screw jacks. Data analysis helps optimize the operation, predict failures, and schedule maintenance tasks proactively.

- Safety Systems: Advanced monitoring and feedback systems can contribute to the safety of screw jack operations. By integrating safety features such as limit switches, emergency stop buttons, or overload protection systems, potential risks or malfunctions can be detected and appropriate actions can be taken to prevent accidents or damage.

By integrating screw jacks with advanced monitoring and feedback systems, precise control, automation, data-driven decision-making, and enhanced safety can be achieved. This integration is particularly beneficial in applications where accuracy, repeatability, and real-time control are critical, such as in industrial automation, robotics, material handling, and assembly processes.

Can screw jacks be used for both light-duty and heavy-duty applications?

Yes, screw jacks are versatile mechanical devices that can be used for both light-duty and heavy-duty applications. Their design and construction allow them to handle a wide range of loads, making them suitable for various industrial, commercial, and residential tasks. Here’s how screw jacks are used in both light-duty and heavy-duty applications:

- Light-Duty Applications: Screw jacks find application in numerous light-duty tasks where precise positioning, lifting, or adjustment is required. Examples of light-duty applications include:

- Workbenches and assembly stations: Screw jacks can be employed to adjust the height of workbenches or assembly stations, allowing operators to work at comfortable levels.

- Stage and theater equipment: Screw jacks are used to raise or lower stage platforms, lighting fixtures, or props, allowing for easy setup and adjustments during performances.

- Medical and healthcare equipment: Screw jacks are utilized in medical beds, examination tables, or dental chairs to enable height adjustments for patient comfort and medical procedures.

- Optical and laboratory equipment: Screw jacks provide precise vertical positioning in optical systems, microscopes, or laboratory setups, ensuring accurate alignment and focus.

- Residential applications: Screw jacks can be used in home applications, such as adjustable tables, ergonomic furniture, or lifting mechanisms for storage units.

- Heavy-Duty Applications: Screw jacks are also capable of handling heavy-duty applications that involve substantial loads and demanding conditions. Examples of heavy-duty applications include:

- Industrial machinery: Screw jacks are utilized in various industrial machinery, including presses, injection molding machines, or material handling equipment, to provide precise control and lifting capabilities.

- Construction and infrastructure projects: Screw jacks are employed in construction tasks, such as formwork systems, scaffolding, or temporary structures, for lifting, leveling, or supporting heavy loads.

- Transportation and automotive: Screw jacks find application in automotive lifts, vehicle maintenance equipment, or cargo handling systems, enabling the lifting and positioning of heavy vehicles or loads.

- Shipbuilding and offshore industries: Screw jacks are used in shipbuilding and offshore applications for tasks such as aligning sections, adjusting propeller pitch, or lifting heavy components during construction or maintenance.

- Mining and heavy equipment: Screw jacks are utilized in mining machinery, cranes, or heavy equipment for load positioning, maintenance, or stabilization.

It’s important to note that the specific design, size, and load capacity of the screw jack should be matched to the requirements of the application. Manufacturers provide a wide range of screw jack models with varying load capacities, travel distances, and configurations to accommodate both light-duty and heavy-duty applications. Proper selection and installation of the screw jack ensure optimal performance and safety in diverse tasks.

Can you explain the basic principle behind the operation of a screw jack?

The basic principle behind the operation of a screw jack is the conversion of rotational motion into linear motion. A screw jack consists of a threaded shaft, known as the screw, and a nut that engages with the screw’s threads. When the screw is rotated, it moves the nut linearly along its threads, resulting in linear displacement. Here are some key points regarding the basic principle of operation for a screw jack:

- Rotational Motion: The operation of a screw jack begins with the application of rotational motion to the screw. This can be achieved through various means, such as manually turning a handle, using an electric motor, or employing hydraulic or pneumatic systems. The rotational motion is typically applied to the top end of the screw.

- Threaded Shaft: The screw in a screw jack is a threaded shaft with helical grooves running along its length. The threads can be either square or trapezoidal in shape. The pitch of the screw refers to the distance traveled along the screw’s axis for each complete revolution. The pitch determines the linear displacement achieved per rotation.

- Nut Engagement: The nut is a component that engages with the screw’s threads. It is typically a cylindrical or rectangular block with a threaded hole that matches the screw’s threads. The nut is free to move linearly along the screw’s length when the screw is rotated.

- Linear Motion: As the screw is rotated, the nut moves along the screw’s threads, causing linear displacement. The direction and magnitude of the displacement depend on the rotational direction and the pitch of the screw. Clockwise rotation typically results in upward linear displacement, while counterclockwise rotation leads to downward displacement.

- Mechanical Advantage: One of the advantages of a screw jack is its ability to provide a mechanical advantage. The pitch of the screw determines the distance traveled per revolution. By increasing the pitch or using multiple-start threads, the linear displacement achieved per rotation can be increased, allowing for the lifting or lowering of heavier loads with relatively less rotational effort.

- Self-Locking: The friction between the screw and the nut helps to maintain the position of the load once the rotational force is removed. This self-locking characteristic of screw jacks allows them to hold loads in position without requiring continuous power or external braking mechanisms.

In summary, the basic principle behind the operation of a screw jack involves the conversion of rotational motion into linear motion. By rotating the screw, the nut moves along the screw’s threads, resulting in linear displacement. The pitch of the screw determines the distance traveled per revolution, and the self-locking nature of the screw and nut interface helps maintain the position of the load.

editor by Dream 2024-04-26

China high quality High Quality Cast Iron Ltq Coupling Flexible Pin Bushed Coupling Flexible Couplings with Screws screw shaft cleaning

Product Description

High Quality Cast Iron LTQ Coupling Flexible Pin Bushed Coupling Flexible Couplings With Screws

Description:

FCL coupling is widely used for its compact designing,easy installation,convenientmaintenance,small size and light weight.As long as the’relative displacement between shafts is kept within the specified tolerance,the coupling will operate the best function and a longer working life,thus it is greatly demanded in medium and minorpower transmission systems drive by moters,such as speed reducers,hoists,compressor,spining &weaving machines and ball mills,permittable relative displacement:Radial displacement 0.2-0.6mm ; Angel displacemente 0o30′–1o30′

Features:

1. Maintenance, a FCLcoupling doesn’t need maintenance.

2. Environmental, elastic components make FCL coupling applies to a variety of working conditions.

3. Reliable transmission, in case of elastic component is damaged, the coupling spider still keep the transmission processing reliably.

4. Economic, FCL couplings have already been made of optimization design,which make transmission power match the transmission shaft diameter.

5. Good recovery capacity, elastic components can reduce the load at the CZPT moments, and the deviation is a major consideration when designing.

6. Adaptability of misalignment, FCL coupling contains parallel shift, angle shift and axis shift which happen some times.

Parameters:

Applications:

Conveyor: Belt conveyor.AFC conveyor.Chain conveyor.Screw conveyor.

Pump: Water pump, oil pump, slush pump,etc

Fan: Draft fan,fanner, boiler fan,etc

Excavator: Bucket excavator. Bucket wheel excavators.Bucket wheel stacker reclaimer.

Crane: Tower crane.Gantry crane.Bridge crane.

Others: Various elevators.Coal plough.Ball mill.Crusher.Recreation machine.Blender equipment.Centrifuger.Washer.Leather-making machine.

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Connection: | Press Connection |

| Structure: | Disc |

| Flexible or Rigid: | Flexible |

| Material: | Iron |

| Customization: |

Available

| Customized Request |

|---|

How do screw jacks handle challenges like load imbalance or uneven surfaces?

Screw jacks are designed to handle challenges such as load imbalance or uneven surfaces through various mechanisms and features. Here’s how screw jacks address these challenges:

- Load Imbalance: Screw jacks can handle load imbalance by distributing the load evenly across multiple screw jacks. In applications where there is a significant load imbalance, multiple screw jacks can be used in a synchronized system. The synchronization ensures that each screw jack shares the load proportionally, preventing excessive stress on any individual screw jack.

- Self-Locking: Screw jacks have a self-locking feature that allows them to hold their position without the need for continuous power or external braking mechanisms. This self-locking capability helps maintain stability and prevents the load from shifting even in the absence of power or during power loss.

- Anti-Backlash Mechanism: To handle challenges related to backlash or unwanted movement caused by load imbalance or vibration, some screw jacks are equipped with anti-backlash mechanisms. These mechanisms minimize or eliminate the clearance between the screw and the nut, reducing the potential for backlash and ensuring precise positioning and stability.

- Flexible Mounting Options: Screw jacks offer flexible mounting options, which allow for proper alignment and compensation on uneven surfaces. Mounting brackets or couplings can be used to adapt the screw jacks to different orientations or to compensate for variations in the mounting surface. This flexibility ensures that the screw jacks can be securely installed and adjusted to accommodate uneven surfaces.

- Guidance Systems: In some cases, screw jacks may incorporate guidance systems to improve stability and alignment. These guidance systems can include linear guides or rails that guide the movement of the screw, ensuring smooth and accurate operation even when dealing with load imbalance or uneven surfaces.

By employing these mechanisms and features, screw jacks can effectively handle challenges related to load imbalance or uneven surfaces. They provide stability, precise positioning, and the ability to distribute loads evenly, making them suitable for a wide range of applications even in demanding environments.

What role do screw jacks play in optimizing precision and alignment in tasks?

Screw jacks play a crucial role in optimizing precision and alignment in various tasks. They offer precise control and reliable adjustment capabilities that contribute to achieving accurate precision and alignment. Here are some key roles that screw jacks play in optimizing precision and alignment:

- Precise Positioning: Screw jacks provide precise positioning control, allowing for accurate adjustment of height, alignment, or level. The threaded screw mechanism enables fine incremental movements, enabling operators to achieve the desired position with high precision. This level of control is essential in tasks that require precise alignment or positioning, such as assembly lines, machining operations, or optical systems.

- Micro-Adjustments: Screw jacks are capable of micro-adjustments, which are extremely small and precise movements. These micro-adjustments are valuable in tasks that demand fine-tuning and meticulous alignment. By making small, controlled changes using the screw jack, operators can optimize the precision and alignment of components or structures.

- Stability and Load-Bearing: Screw jacks offer stability and reliable load-bearing capabilities. The load is evenly distributed and supported along the screw thread, ensuring stability during tasks that require precision and alignment. This stability is especially important when working with delicate or sensitive components that may be susceptible to misalignment or damage due to external forces.

- Repeatability: Screw jacks facilitate repeatability in precision and alignment tasks. Once a specific position or alignment is achieved, the screw jack can reliably return to that position repeatedly. This repeatability is advantageous in applications that require consistent precision and alignment, such as testing equipment, calibration processes, or scientific experiments.

- Flexibility and Adaptability: Screw jacks offer flexibility and adaptability to optimize precision and alignment in various tasks. They can be easily adjusted and customized to accommodate different requirements, load capacities, and dimensions. Screw jacks are available in different sizes, configurations, and mounting options, allowing for integration into diverse applications and systems.

- Combined with Measurement Systems: Screw jacks can be combined with measurement systems or sensors to enhance precision and alignment. For example, by integrating linear displacement sensors or laser alignment systems, operators can monitor and verify the position or alignment during the task. This combination of screw jacks with measurement systems provides real-time feedback and enables adjustments to achieve optimal precision and alignment.

By providing precise positioning, micro-adjustments, stability, load-bearing capabilities, repeatability, flexibility, and the ability to integrate with measurement systems, screw jacks significantly contribute to optimizing precision and alignment in a wide range of tasks. Their reliable and controllable nature makes them valuable tools in industries such as manufacturing, construction, automation, and research.

How do manufacturers ensure the quality and reliability of screw jack mechanisms?

Manufacturers employ various quality control and testing measures to ensure the quality and reliability of screw jack mechanisms. These measures are implemented throughout the manufacturing process to verify that the screw jack meets the required standards and performance specifications. Here are some common practices manufacturers use to ensure quality and reliability:

- Design and Engineering: Manufacturers invest in robust design and engineering processes to develop screw jack mechanisms that meet the intended specifications. This includes selecting appropriate materials, determining the optimal thread design, and performing structural analysis to ensure the screw jack can handle the expected loads and movements. Thorough design and engineering processes contribute to the overall quality and reliability of the mechanism.

- Material Selection: Manufacturers carefully select materials with the necessary strength, durability, and corrosion resistance for the construction of screw jack mechanisms. High-quality materials, such as alloy steels or stainless steels, are often chosen to ensure the longevity and reliability of the screw jack. Material selection is based on factors such as load requirements, environmental conditions, and industry standards.

- Quality Assurance: Manufacturers implement comprehensive quality assurance processes to monitor and control the manufacturing steps. These processes include inspections, audits, and documentation to ensure that each screw jack meets the specified quality standards. Quality assurance measures may involve checks for dimensional accuracy, thread quality, surface finish, and proper assembly. Through quality assurance, manufacturers can identify and address any potential defects or deviations from the desired specifications.

- Testing and Performance Evaluation: Manufacturers conduct rigorous testing and performance evaluations to verify the functionality, load capacity, and reliability of screw jack mechanisms. This may involve load testing, endurance testing, and cycling tests to simulate real-world operating conditions. Testing helps validate the performance of the screw jack and ensures that it can handle the intended loads and movements without failure or significant degradation over time.

- Compliance with Standards: Manufacturers ensure that screw jack mechanisms comply with relevant industry standards and regulations. Compliance with standards such as ISO (International Organization for Standardization) or specific industry standards provides assurance of the quality and reliability of the product. Manufacturers may obtain certifications or undergo third-party audits to validate compliance with these standards.

- Customer Feedback and Continuous Improvement: Manufacturers value customer feedback and use it to drive continuous improvement in the design, manufacturing, and performance of screw jack mechanisms. By actively seeking input from customers and end-users, manufacturers can identify areas for enhancement and implement changes to improve the quality and reliability of their products.

By implementing stringent design processes, careful material selection, thorough quality assurance, testing and performance evaluation, compliance with standards, and continuous improvement practices, manufacturers ensure the quality and reliability of screw jack mechanisms. These measures help deliver screw jacks that meet the industry’s expectations for performance, safety, and durability.

editor by Dream 2024-04-26

China Standard Large Stock C45 Steel Blackening Single Piece Clamping Ring Shaft Lock Collar screwdriver shaft

Product Description

Product Description

Product Features:

1.Effective on hard and soft shafts

2.Cost effective collar design

3.Easy installation and adjustment

Types of shaft collars:

Solid Setscrew shaft collar,Hex bore shaft collar,One Piece shaft collar,Two

Piece shaft collar,Threaded shaft collar,Single split shaft collar,Double split shaft collar

Our products can be made according to Climax,Holo-Krome,Stafford,Ruland etc.

Note of single split shaft collar:

1.Material:AL,Steel,Stainless steel,Alloy,Copper,Plastic

2.Finish: Black oxide, self-color, oiled, zinc plated

3.Processes:Broaching/ Hobbing/ Slotting/tapping

4.Package:box/carton/wooden case

5.Lead time:20-35 days

6.ISO9001:2008 Certificated

Two Piece Shaft Collars, or Split Collars as they are sometimes called, cosist of a split two-part assembly. This 2 part design can help reduce the labour required by facilitating quick and easy fitting and removal.

Product Parameters

Detailed Photos

Our Advantages

Competitive Price

Shorter Delivery Date

Technical R&D Team

Professional Manufacturer for 20+ years

Strict QC Management:ISO9001:2008

Supplier of Well-known Brands

Main Products

|

Timing Pulley V Belt Pulley Taper Lock Bush Locking Device Sprockets Gears& Racks Shaft Collar Transmission Belts Universal Joint Couplings |

Company Profile

ZheJiang Mighty Machinery Co., Ltd. specializes in manufacturing mechanical power transmission components. We Mighty is the branch of SCMC Group, a wholly state-owned company, established in 1980.

About us:

-3 manufacturing factories

We have 5 technical staff, our FTY have strong capacity for design and process design, and more than 70 workers and double shift eveyday.

-Large quality of material purchase and stock

We ensure both the quality and low cost for material and production.

-Strick quality control

We have strict process inspection and final production inspection to ensure the perfect quality.

-20 years of machinery experience

MIGHTY’s products are mainly exported to Europe, America and the Middle East market. With the top-ranking management, professional technical support and abundant export experience, MIGHTY has established lasting and stable business partnership with many world famous companies and has gained good reputation from CHINAMFG customers.

FAQ

1. Are you a trading company or manufacturer?

We are a manufacturer of 20+ years with owning 3+ factories and also do exporting business.

2. What’s your MOQ?

Usually 1 piece for standard parts.

3. How long is your delivery time?

Around 4-6 business days for standard parts and around 25-30 business days for bulk production.

4. Do you support OEM/ODM?

Yes. Welcome for CZPT out.

5. Do you offer both inch and metric shaft collar?

Yes we do.

6. What is your payment terms?

T/T, Paypal, L/C, D/P, D/A, Western Union, etc. in flexible way.

If you have another question, pls feel free to contact me without hesitation as below:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard or Non-Standard |

|---|---|

| Feature: | Anti-Static, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Heat-Resistant, Alkali-Resistant, Skid-Resistance, Wear-Resistant, Acid-Resistant, High Temperature-Resistance |

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery |

| Surface Treatment: | Plain Finish/Black Oxide Finish/Zinc Plated Finish |

| Material: | Steel/Stainless Steel/Cast Iron |

| Bore Size: | 3-60mm |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can screw jacks be adapted for use in both indoor and outdoor environments?

Yes, screw jacks can be adapted for use in both indoor and outdoor environments. They are versatile mechanical devices that can be designed and manufactured to withstand various environmental conditions. Here’s how screw jacks can be adapted for both indoor and outdoor use:

- Enclosure and Sealing: When screw jacks are intended for outdoor use, they can be equipped with enclosures and sealing mechanisms to protect the internal components from environmental factors such as moisture, dust, or debris. These enclosures are typically made from durable materials like stainless steel or corrosion-resistant coatings to ensure long-term protection.

- Corrosion Resistance: Outdoor environments often expose equipment to corrosive elements. To address this, screw jacks can be manufactured with corrosion-resistant materials or coatings. Stainless steel or zinc plating are commonly used to enhance the corrosion resistance of screw jacks, making them suitable for outdoor applications where exposure to moisture, humidity, or chemicals is expected.

- Weatherproofing: Screw jacks can be designed with weatherproofing features to resist environmental conditions such as rain, snow, or extreme temperatures. This may include seals, gaskets, or protective covers that prevent water or debris from entering the internal components, ensuring reliable operation in outdoor environments.

- UV Resistance: Outdoor applications often expose equipment to ultraviolet (UV) radiation from sunlight. Screw jacks can be manufactured using materials that are UV-resistant or incorporate UV-protective coatings. This helps prevent degradation or discoloration of the components due to prolonged exposure to sunlight.

- Temperature Considerations: Screw jacks can be designed to operate within a wide temperature range to accommodate diverse outdoor environments. Specialized lubricants and materials with high-temperature stability can be used to ensure proper functioning and prevent damage or degradation in extreme temperature conditions.

- IP Ratings: In certain applications, screw jacks may require specific Ingress Protection (IP) ratings to ensure their suitability for outdoor use. IP ratings indicate the level of protection against solids and liquids. Screw jacks can be manufactured with specific IP ratings to meet the environmental requirements of different outdoor applications.

By incorporating these adaptations, screw jacks can be effectively used in both indoor and outdoor environments. Whether it’s in manufacturing facilities, construction sites, or outdoor maintenance tasks, screw jacks provide reliable performance and can withstand the challenges posed by various environmental conditions.

How do manufacturers ensure the durability and longevity of screw jacks?

Manufacturers employ various strategies and design considerations to ensure the durability and longevity of screw jacks. These measures aim to enhance the structural integrity, reliability, and resistance to wear and tear. Here are some key approaches manufacturers use to ensure the durability and longevity of screw jacks:

- High-Quality Materials: Manufacturers use high-quality materials in the construction of screw jacks to enhance their durability. Components such as screws, nuts, housing, bearings, and load-bearing parts are often made from materials such as hardened steel alloys or other durable metals. These materials offer excellent strength, resistance to deformation, and robustness, ensuring that the screw jacks can withstand heavy loads and prolonged use.

- Surface Treatments: Surface treatments and coatings are applied to screw jack components to improve their resistance to corrosion, abrasion, and wear. Common surface treatments include electroplating, powder coating, or applying specialized protective coatings. These treatments provide a layer of defense against environmental factors, such as moisture, chemicals, or abrasive particles, which can degrade the components and compromise the longevity of the screw jacks.

- Precision Manufacturing: Precision manufacturing processes are employed to ensure the accurate fabrication of screw jacks. Tight tolerances and meticulous machining techniques are utilized to achieve proper fit and alignment of components. This precision manufacturing minimizes mechanical play, reduces friction, and optimizes the overall performance of the screw jacks, contributing to their durability and longevity.

- Load Capacity and Safety Margins: Manufacturers carefully determine the load capacity of screw jacks and incorporate safety margins to ensure their long-term durability. By specifying load capacities that exceed the expected maximum loads, manufacturers provide a safety buffer that prevents the screw jacks from operating near their limits. This approach minimizes stress on the components and extends their lifespan, reducing the risk of premature failure or damage.

- Regular Maintenance Guidelines: Manufacturers provide maintenance guidelines and recommendations for screw jacks. These guidelines outline routine maintenance tasks, such as lubrication, inspection, and cleaning, that should be performed to ensure optimal performance and longevity. Following these maintenance guidelines helps prevent the accumulation of debris, corrosion, or other factors that could negatively impact the durability of the screw jacks.

- Quality Assurance Testing: Manufacturers conduct rigorous quality assurance testing to validate the durability and longevity of screw jacks. These tests may include performance testing, load testing, endurance testing, and environmental testing. By subjecting the screw jacks to stringent testing conditions, manufacturers can verify their performance, identify potential weaknesses, and make design improvements to enhance durability and longevity.

By using high-quality materials, applying surface treatments, employing precision manufacturing, incorporating load capacity and safety margins, providing maintenance guidelines, and conducting quality assurance testing, manufacturers ensure the durability and longevity of screw jacks. These measures help to deliver reliable and long-lasting products that can withstand demanding applications and operating conditions.

Can you explain the basic principle behind the operation of a screw jack?

The basic principle behind the operation of a screw jack is the conversion of rotational motion into linear motion. A screw jack consists of a threaded shaft, known as the screw, and a nut that engages with the screw’s threads. When the screw is rotated, it moves the nut linearly along its threads, resulting in linear displacement. Here are some key points regarding the basic principle of operation for a screw jack:

- Rotational Motion: The operation of a screw jack begins with the application of rotational motion to the screw. This can be achieved through various means, such as manually turning a handle, using an electric motor, or employing hydraulic or pneumatic systems. The rotational motion is typically applied to the top end of the screw.

- Threaded Shaft: The screw in a screw jack is a threaded shaft with helical grooves running along its length. The threads can be either square or trapezoidal in shape. The pitch of the screw refers to the distance traveled along the screw’s axis for each complete revolution. The pitch determines the linear displacement achieved per rotation.

- Nut Engagement: The nut is a component that engages with the screw’s threads. It is typically a cylindrical or rectangular block with a threaded hole that matches the screw’s threads. The nut is free to move linearly along the screw’s length when the screw is rotated.

- Linear Motion: As the screw is rotated, the nut moves along the screw’s threads, causing linear displacement. The direction and magnitude of the displacement depend on the rotational direction and the pitch of the screw. Clockwise rotation typically results in upward linear displacement, while counterclockwise rotation leads to downward displacement.

- Mechanical Advantage: One of the advantages of a screw jack is its ability to provide a mechanical advantage. The pitch of the screw determines the distance traveled per revolution. By increasing the pitch or using multiple-start threads, the linear displacement achieved per rotation can be increased, allowing for the lifting or lowering of heavier loads with relatively less rotational effort.

- Self-Locking: The friction between the screw and the nut helps to maintain the position of the load once the rotational force is removed. This self-locking characteristic of screw jacks allows them to hold loads in position without requiring continuous power or external braking mechanisms.

In summary, the basic principle behind the operation of a screw jack involves the conversion of rotational motion into linear motion. By rotating the screw, the nut moves along the screw’s threads, resulting in linear displacement. The pitch of the screw determines the distance traveled per revolution, and the self-locking nature of the screw and nut interface helps maintain the position of the load.

editor by Dream 2024-04-25

China Professional Custom Made High Precision CNC Turning Machined Polished Stainless Steel 304 316 CZPT Shaft ball screw shaft coupler

Product Description

| Model NO. | Custom Parts | Application | Fastener, Auto and Motorcycle Accessories, Hardware Tool, Machinery Accessory |

| Standard | GB, EN, China GB Code, JIS Code, TEMA, ASME | Surface Treatment | Anodizing |

| Production Type | Mass Production | Machining Method | CNC Machining |

| Material | Nylon, Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron | Drawing Type | Dwg, Dxf, Step, Iges, Pdf, STP, etc. |

| Tolerance | +/-0.002mm, or Customized | Roughness | Ra0.2-Ra3.2 , or Customized |

| Surface Finish | Anodization, Plating, Passivation, Polish, Brush | Colors | Blue, Red, Black, Gold, Orange, Green, Gray, White |

| Sample Service | Available | Part Name | CNC Machining Parts |

| Service | Machining, Assembly, Surface Treatment, etc. | Dimensions | Customized |

| Lead Time | 1-4 Weeks Depends on Requests | MOQ | 1 PCS, But Over 100PCS Is a Price Break Point |

| Machining Capability | 3,4,5 Axis CNC Milling, CNC Turning, Sheet Metal | Price | Negotiable as Per Request |

| Transport Package | Foam, Carton | Specification | Custom dimension |

| Trademark | Custom | Origin | China |

| HS Code | 84799 0571 0 | Production Capacity | 50000PCS |

Product Description

| Parts Application | Industrial Parts, Bikes, Engine parts, Robotic Parts, Decoration, BMX, EDC, yoyo, CZPT parts, Electronics aluminum parts, Toys parts, Gears, Car parts, 4X4 parts, Medical Parts. Oil industry parts. Audio equipment parts, Musical Instrument parts |

||

| Machining Tolerance | The best tolerance is +/-0.002mm, can do as per your request. | ||

| Roughness | Ra0.2-Ra3.2, (as per specification) | ||

| Quotation | Need to know material, quantity, surface treatment, and another special request before sending you a quotation | ||

| Software Available | CAD, CHINAMFG Works, UG, CAD/CAM/CAE, PDF. | ||

| Surface Finish | Matte, Glossy, Tumbling, Smooth, beadblasting. | ||

| Surface Treatment | Anodization, Plating, Passivation, Polishing, Brushing. | ||

| Materials Available | Aluminum, Brass, Copper, Stainless Steel, Titanium, PVC, ABS, PEEK, Nylon, Delrin, Acrylic, Steel | ||

| Inspection instruments | Height Gauge, CMM, Caliper, Electronics Scale, Micrometer/Microcaliper, Gage Blocks, Pin Gauge. | ||

| Service Available | 1. CNC machining, CNC milling, CNC turning, Sheet Metal, Laser cutting, 2. Assemble (Using press fit or other technology), 3. Packing for “ready to sale” products, 4. Customized Packaging, 5. Relative accessory purchasing. |

||

Sample Parts Show

Why Choose us

Our Equipments

Test Report Sample

Certifications

Our Package

FAQ

| Q1. Are you a genuine manufacturer? | |||

| Yes, all the products are produced in our ISO9001:2015 certified factory; We are also a company registered by China Customs with the right to export and import. | |||

| Q2. What should I offer to get your quotation? | |||

| Please offer us your detailed information for the product, such as drawings with 2D/3D by software Pro/E, Auto CAD, SolidWorks, UG etc; as well as materials, surface treatment, quantity, package. Any special requirements should be highlighted especially for tolerance. | |||

| Q3. Can we get a complete product besides CNC parts? | |||

| To some extent, yes, we can. But firstly we need assess feasibility. | |||

| Q4. What’s your top process tolerance? | |||

| Now our top process tolerance is ± 0.005mm. | |||

| Q5. What are your sample policy and trade/payment terms? | |||

| We can offer the free samples with total value less than USD10; while the buyers should bear shipping cost and import VAT. | |||

| Ex-works, FOB ZheJiang /HangZhou, CIF etc. would be OK for us. | |||

| As for the payment, small value is recommended by Paypal or Western Union; larger amount by T/T, 50% as deposit, 50% before shipment. | |||

| Q6. How about the warranty? | |||

| The warranty is for 1 year. As you know, our CNC parts have a long lifespan except for damaged by operating inappropriately. | |||

| Q7. What’s your policy for RMA? | |||

| All defective products should be confirmed by us based on the customers’ RMA list and photos first, then we’d like to refund the money or compensate the goods by free of charge accordingly. | |||

| Q8. I want to keep our design in confidence; can we CHINAMFG NDA? | |||

| Sure, to protect customers’ profit is our obligatory responsibility, signed NDA would be valid to both of us. | |||

| . | |||

| What benefit we can get from you? | |||

| 1) Competitive price | |||

| 2) High quality control : 100% full inspection before shipment | |||

| 3) High precision, tolerance can be ± 0.005mm | |||

| 4) Fast lead time (5-7days for samples, 12-15 days for mass production) | |||

| 5) Non-standard//OEM//customized service provided | |||

| 6) No MOQ, small QTY is acceptable. | |||

| 7) Factory ISO 9001 certification, ROHS material used | |||

| 9) Professional export packing: separate Blister plastic box or Bubble Wrap/Pearl Wool +Carton+ Wooden Case, keep no scratch and damage |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard: | GB |

|---|---|

| Surface Treatment: | Anodizing, Painting, Phosphating, Passivation… |

| Customization: | Yes |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What role do screw jacks play in the precision of assembly line operations?

Screw jacks play a crucial role in ensuring the precision of assembly line operations. They are widely used in manufacturing and assembly processes where accurate positioning, alignment, and control are essential. Here’s how screw jacks contribute to the precision of assembly line operations:

- Precise Positioning: Screw jacks provide precise and controlled linear motion, allowing for accurate positioning of components, parts, or tools on the assembly line. The screw mechanism of the screw jack enables fine adjustments with high positional accuracy, ensuring that each component is correctly placed and aligned according to the required specifications.

- Height Adjustment: Screw jacks are commonly used for height adjustment applications in assembly lines. They allow for easy and precise vertical movement, enabling operators to align workstations, fixtures, or equipment at the optimal height for efficient assembly operations. The ability to fine-tune the height with screw jacks ensures ergonomic working conditions and promotes worker comfort and productivity.

- Load Handling: Screw jacks have the capability to handle a wide range of loads, from light to heavy. This makes them suitable for assembly line operations that involve different types of components or equipment with varying weights. By providing reliable load support and stability, screw jacks contribute to the precision of assembly line operations by ensuring that the load is properly supported and aligned during the assembly process.

- Force Control: Screw jacks offer precise force control capabilities, allowing operators to apply consistent and controlled forces during assembly operations. This is particularly important for tasks that require delicate handling or specific force requirements, such as tightening bolts, fastening components, or applying pressure for proper fitment. The force control provided by screw jacks helps maintain the required precision and avoids overloading or damaging the assembly components.

- Synchronization: In assembly line operations that involve multiple workstations or moving parts, screw jacks can be synchronized to ensure coordinated movement. By mechanically or electrically linking the screw jacks together, they can

What are the common signs of wear or issues that might require screw jack maintenance?

Regular maintenance is important for ensuring the proper functioning and longevity of screw jacks. It helps identify and address potential issues before they escalate into more significant problems. Here are some common signs of wear or issues that might indicate the need for screw jack maintenance:

- Unusual Noise: If a screw jack starts producing unusual noises during operation, such as grinding, squeaking, or knocking sounds, it could indicate a problem. These noises may be a result of worn or damaged components, inadequate lubrication, misalignment, or other mechanical issues. Prompt maintenance is necessary to diagnose and resolve the source of the noise.

- Increased Friction: If the movement of the screw jack becomes more difficult or requires excessive force, it could indicate increased friction within the mechanism. This may be caused by insufficient lubrication, contaminated lubricant, or worn components. Addressing the friction issue through maintenance, including lubrication and inspection of components, is important to prevent further damage and ensure smooth operation.

- Excessive Play or Backlash: Excessive play or backlash refers to unwanted movement or looseness in the screw jack assembly. It can occur due to worn or damaged components, improper assembly, or misalignment. Excessive play can negatively impact the precision, stability, and load-bearing capacity of the screw jack. Maintenance should be conducted to identify the cause of the play and rectify it to restore proper functionality.

- Irregular Movement: If the screw jack exhibits irregular or jerky movement instead of smooth and consistent operation, it may indicate issues with the drive mechanism, misalignment, or worn parts. Irregular movement can affect the performance and accuracy of the screw jack, potentially leading to safety hazards or reduced efficiency. Maintenance is necessary to diagnose and address the underlying causes of irregular movement.

- Leakage or Seal Damage: Screw jacks equipped with hydraulic or lubricant-filled systems may experience leakage or seal damage over time. Leakage can result in a loss of lubrication or hydraulic fluid, leading to inadequate lubrication, reduced performance, or system failure. Regular inspection and maintenance of seals, gaskets, and fluid levels are necessary to identify and rectify any leaks or seal damage.

- Visible Wear or Damage: Physical inspection of the screw jack is essential to identify visible signs of wear or damage. This may include worn threads, cracked or damaged housing, bent or misaligned components, or signs of corrosion. Any visible wear or damage should be addressed through maintenance to prevent further deterioration and ensure safe and reliable operation.

Regular inspection and maintenance are crucial to detect and address these signs of wear or issues promptly. It is recommended to follow the manufacturer’s guidelines for maintenance intervals and procedures to ensure the optimal performance and longevity of screw jacks.

What factors should be considered when selecting the right screw jack for an application?

When selecting the right screw jack for an application, several factors should be taken into consideration. These factors help ensure that the chosen screw jack meets the specific requirements of the application. Here are the key factors to consider:

- Load Capacity: Determine the maximum load that the screw jack needs to lift or support. Consider both the static load (the weight of the load when stationary) and the dynamic load (additional forces or vibrations that may be present during operation). Select a screw jack with a load capacity that exceeds the application’s requirements to ensure safe and reliable operation.

- Travel Distance: Determine the required travel distance or height adjustment range of the screw jack. Consider both the minimum and maximum travel distances needed for the application. Ensure that the selected screw jack can provide the required travel distance without exceeding its mechanical limits.